What are the advantages and disadvantages of injection moulding?

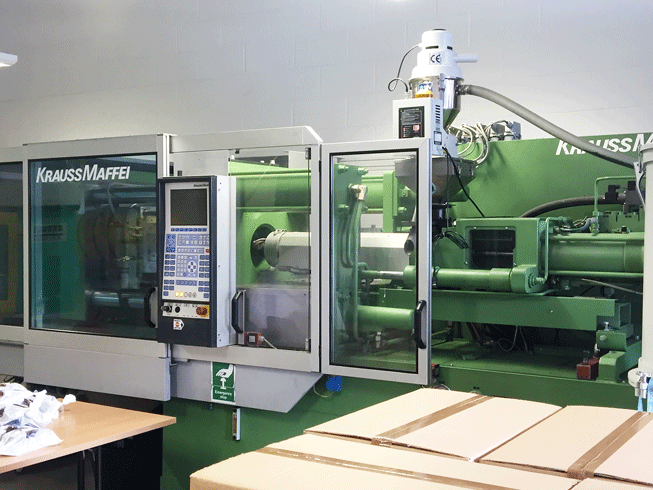

Injection moulding is one of the most commonly used methods of producing identical plastic products in high volumes.

As a result, one might be fooled into thinking it must be simple to get a product to market through this avenue. However, as with every process, it is important to understand the specific design restrictions that must be adhered to in order to facilitate the obvious benefits of successfully producing cost effective, high quality parts.

To help, we have very simply laid out the advantages and disadvantages to consider.

Please be aware, however, that the following guidelines apply to what we would consider to be conventional injection moulding (quantities of 100,000+) and may appear at first glance to be fairly prohibitive if you are looking to develop a product with numbers out of this norm.

Low volume production possibilities

The good news is Plunkett Associates have spent many years developing strategies and techniques in order to take away some of the issues identified below, particularly for parts that would traditionally be considered too difficult or unusual to mould.

In addition, we are specialists in making injection moulding far more cost effective for much lower quantities of parts than is more commonly expected.Using a hybrid of techniques, our low volume production tooling allows us to customise to client/geometry/quantities. The result is a mould tool that reflects the requirement and opens up an exciting option to produce high quality, yet low volume components.

As an ISO:9001:2015 Quality System certified supplier, we are confident we can help with your requirements so please feel free to give us a call.

Advantages of injection moulding

1) Fast production and highly efficient. Injection moulding can produce an incredible amount of parts per hour. Speed depends on the complexity and size of the mould, anywhere between 15-120 seconds per cycle time.

2) Low labour costs. Plastic injection moulding is an automated process whereby a majority of the process is performed by machines and robotics, which a sole operator can control and manage. Automation helps to reduce manufacturing costs, as the overheads are significantly reduced.

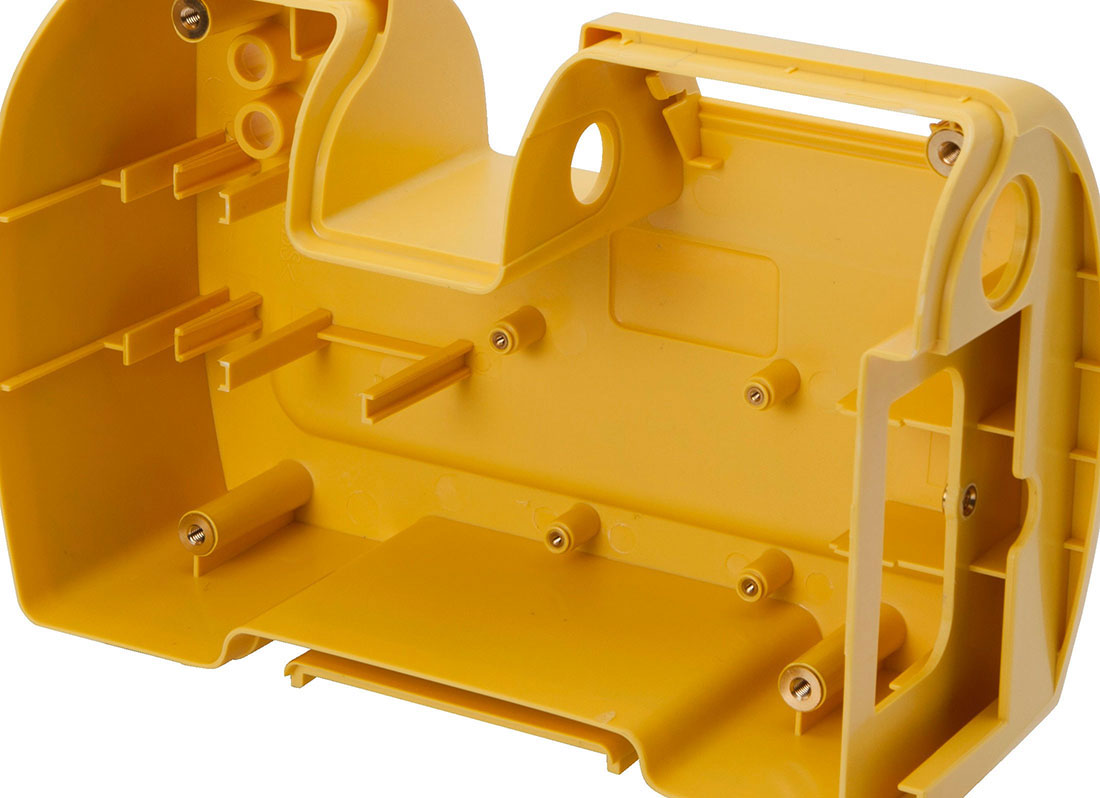

3) Design flexibility. The moulds themselves are subjected to extremely high pressure. As a result, the plastic within the moulds is pressed harder and allows for a large amount of detail to be imprinted onto the part and for complex or intricate shapes to be manufactured.

4) High-output production. Thousands of parts can be produced before the tooling needs to be maintained.

5) Large material choice. There is a large selection of polymer resins to choose from. Multiple plastic materials can also be used simultaneously; for example, TPE can be overmoulded onto PP parts.

6) Low scrap rates. Injection moulding produces very little post-production scrap relative to traditional manufacturing processes. Any waste plastic typically comes from the sprue and runners. Any unused or waste plastic, however, can be reground and recycled for future use.

7) Ability to include inserts. Metal or plastic inserts can be insert moulded.

8) Good colour control. Plastic parts can be manufactured in any required colours with the use of masterbatches or compounding.

9) Product consistency. Injection Moulding is a repeatable process, in other wordsthe second part you produce is going to be identical to the first one etc. This is a huge advantage when trying to produce high tolerances and part reliability in high volumes.

10) Reduced finishing requirements. There is often very little post-production work required as parts usually have a good finished look upon ejection.

11) Enhanced Strength. When plastic injection moulding, it is possible to use fillers in the moulding material. These fillers reduce the density of the plastic whilst it is being moulded, and can help add greater strength to the completed part.

Disadvantages of injection moulding

1) High tooling costs and long set up lead times. Up front costs are high due to the design, testing, and tooling required. There is the initial design and prototyping (probably via CNC or 3D printing), then the design of a prototype mould tool to produce replicas of the part in volume. Lastly, and only after extensive testing during both stages, you can finally injection mould a part.

2) Part design restrictions. Plastic parts must be designed with injection moulding consideration and must follow the basic rules of injection moulding, for example:

- Avoid under cuts and sharp edges as much as possible

- Use uniform wall thicknesses to prevent inconsistencies in the cooling process resulting in defects like sink marks.

- Draft angles are encouraged for better de-moulding.

Don’t forget, because tools are typically made from steel or aluminum, it can be difficult to make design changes. If you need to add plastic to the part you can make the tool cavity larger by cutting away steel or aluminum. But in order to take away plastic, you need to decrease the size of the tool cavity by adding aluminum or metal to it. This is extremely difficult and in many cases might mean scrapping the tool (or part of it) and starting over.

In addition, the weight and size of the part will determine the tool size and necessary press size. The larger the part, the more difficult and expensive it will be.

3) Small runs of parts can be costly. Due to the complexity of tooling, and the necessity to rid the machine of all previous material before the next product can be made, setup time can be quite lengthy. Therefore small runs of parts have traditionally always been thought of as too expensive to injection mould.

In summary

Injection moulding is a great process! The range of materials and colours is huge and there is no “abs like’ that we get in 3D Printing, its the real thing. Parts are repeatable and tight tolerance. The only potential downside is the tooling, but as we said at the beginning of this article, we’ve got that covered, with options to suit most requirements.