Analysis

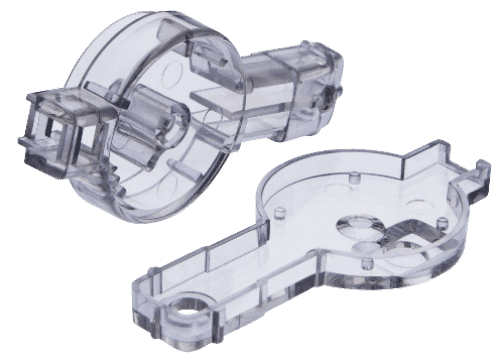

At Plunkett Associates we have elected to run Solidworks as our primary 3D modelling package and then augment this with specialist software as required.

Thermal and mechanical analysis

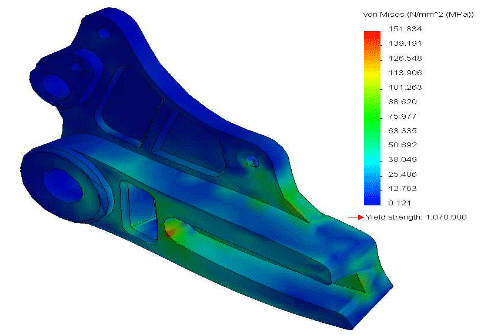

As such we can work with 3D models to analyse their strength, not just at the component level but also at the assembly level, and look at thermal analysis to predict component temperatures in a variety of different environmental conditions.

When analysing an assembly to ensure that the required margins of safety are achieved it is important to be able to define the loading and restraining criteria. The way in which a component is mounted can have a huge impact on how it will deform and the displacement it undergoes.

When analysing an assembly to ensure that the required margins of safety are achieved it is important to be able to define the loading and restraining criteria. The way in which a component is mounted can have a huge impact on how it will deform and the displacement it undergoes.

When we look at heat transfer, be it extracting heat from an LED or microchip, or ensuring that a housing contains sufficient insulation that it can be safely handled, it is equally important to be able to define the environment.

Today there are databases of materials giving easy access to most material characteristics, so be the work thermal or mechanical, different materials can be analysed to show their relative performance. This can be useful in trying to reduce cost, yet retaining a desired performance capability.

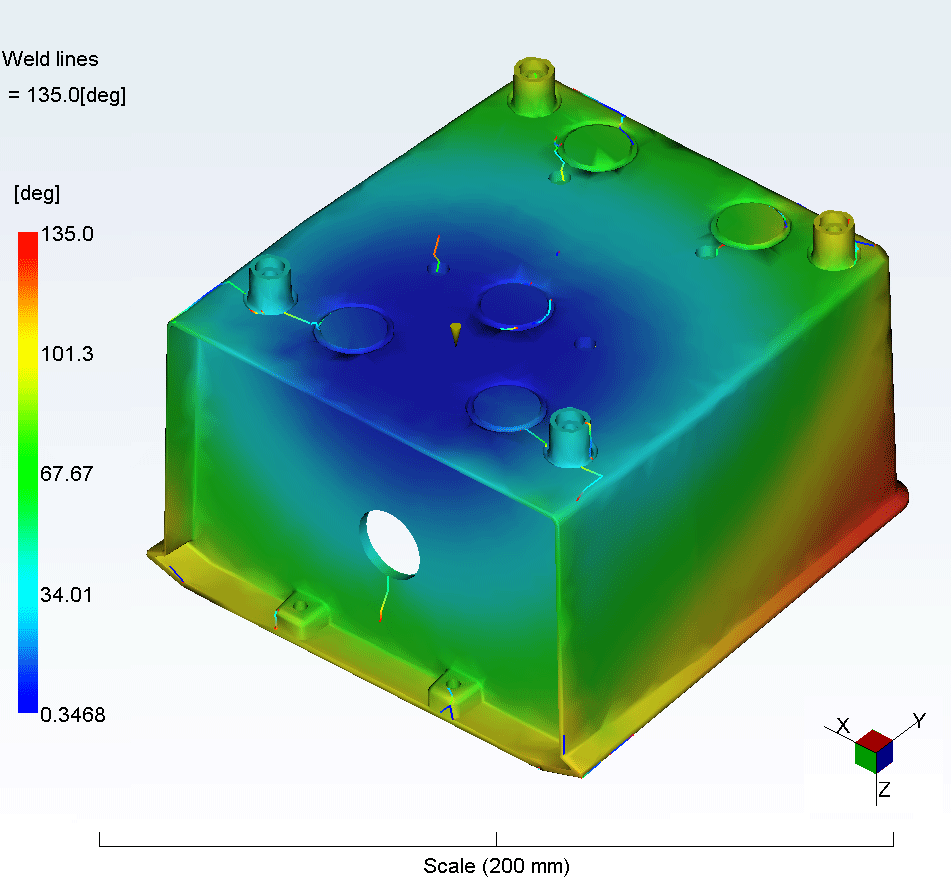

Moldflow analysis

We use Moldflow on projects that will be injection moulded, be they our designs or client designs. With it we can simulate the way in which an injection mould will fill, how long that will take and the temperatures involved.

We use Moldflow on projects that will be injection moulded, be they our designs or client designs. With it we can simulate the way in which an injection mould will fill, how long that will take and the temperatures involved.

We can predict the location of weld lines for example, and move the gates around in software rather than steel, so saving time and money.

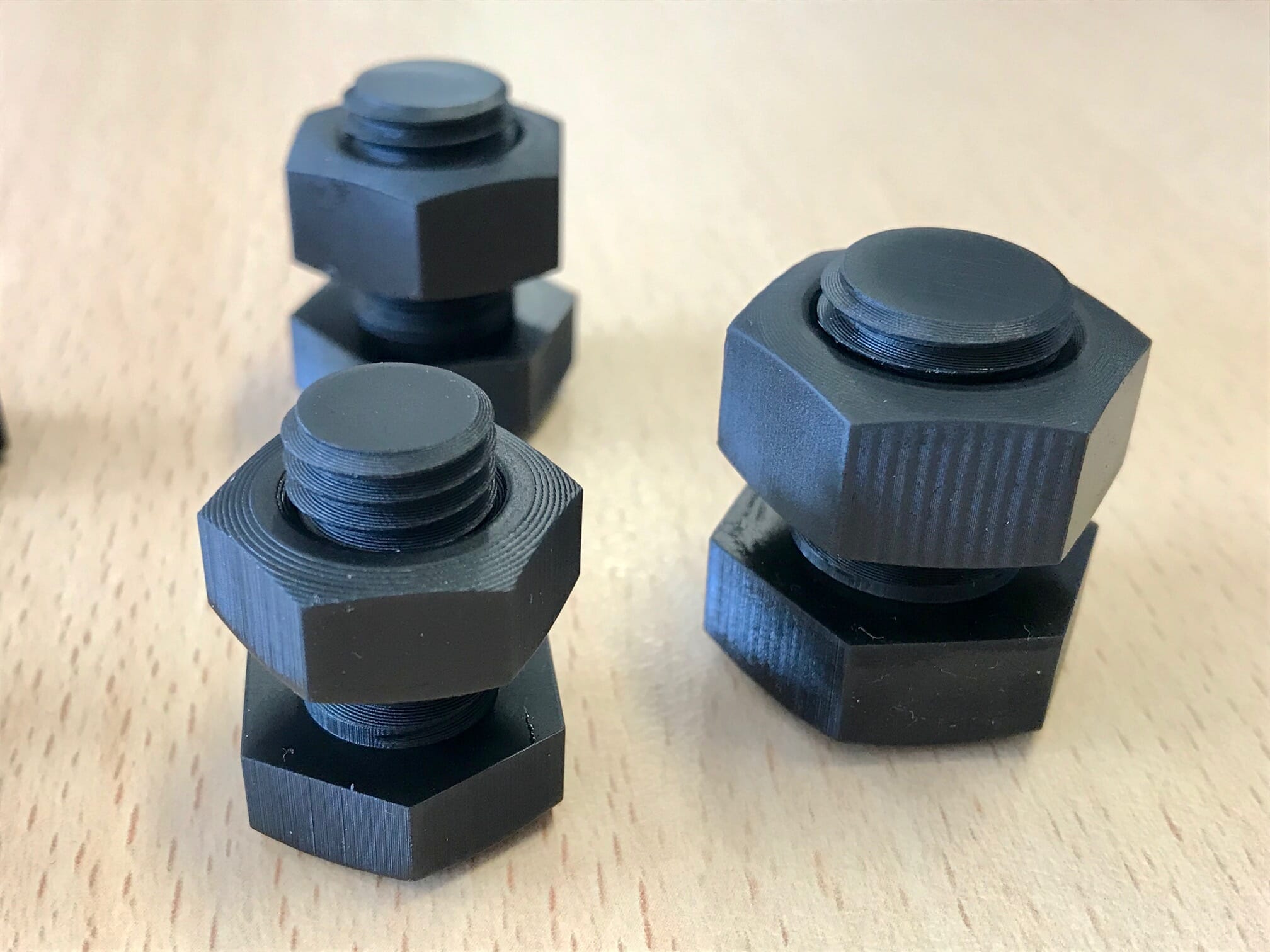

Empirical testing supports the analysis

Whilst some might question the accuracy of theoretical analysis, it can undoubtedly show the benefits or shortcomings of relative design options. If absolute values are required then the conservative option would always involve some empirical testing to support the analysis!

As a tool to get the desired performance, it is a great help and with the design data available, it is a tool not to be ignored.

If you have a project that would benefit from analysis, please contact us. In addition to our in-house capability, we have experts we can call on for further analysis if needed, to help us get the best solution for your design.