Stereolithography (SLA)

Produces accurate 3D models with a range of material choices. High Res SLA and Micro SLA for smaller parts.

.png) This process has been widely implemented, and well proven, with a variety of different materials available.

This process has been widely implemented, and well proven, with a variety of different materials available.

And Plunkett Associates should know; Tim Plunkett, having already established two pioneering additive manufacturing companies, has over 20 years experience in this industry and a wealth of knowledge and contacts as a result.

Stereolithography (SLA)

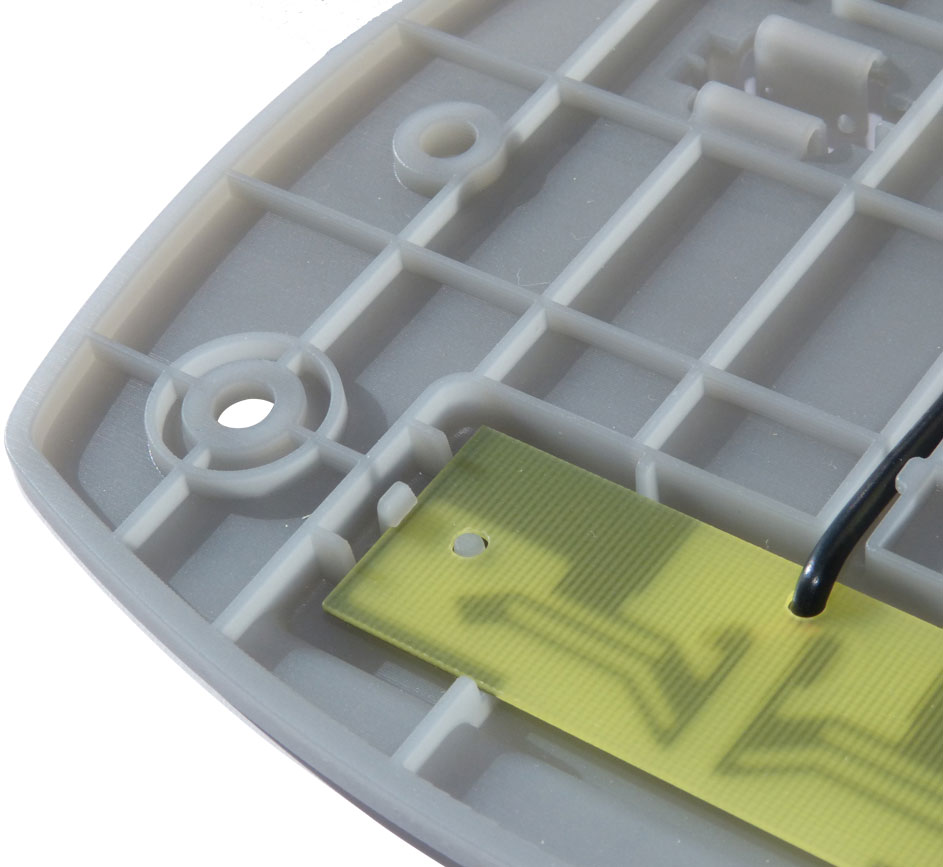

With feature resolution ranging from around 0.1-0.2mm (material dependent), and a maximum build envelope of 650x750x550, there are few designs that can’t be brought to life using Stereolithography (SLA).

A wide variety of resins are available, from all over the world, however many of them will only work in the machines they have been designed for. Materials have evolved to emulate commonly used plastics, such as ABS and polypropylene, with virgin parts displaying similar and in some cases superior properties to the materials they are imitating. This change in performance can result in many similar resins demonstrating your desired properties.

Composite-filled resins are also available for use in Stereolithography (SLA). These offer a large increase in stiffness, a moderate increase to mechanical strength and increased performance at higher temperatures; making Stereolithography (SLA) a high performance solution to your design needs.

Due to the nature of the filler in the resin, components with high feature definition, and small passageways, may sometimes pose barriers to its implementation.

Virgin parts give solid mechanical properties, however to get the highest performance from the resins, post curing in the form of UV and/or thermal treatment may be necessary.

Whilst deliveries are always tailored to customer requirements, a typical turnaround would be 5-7 days.

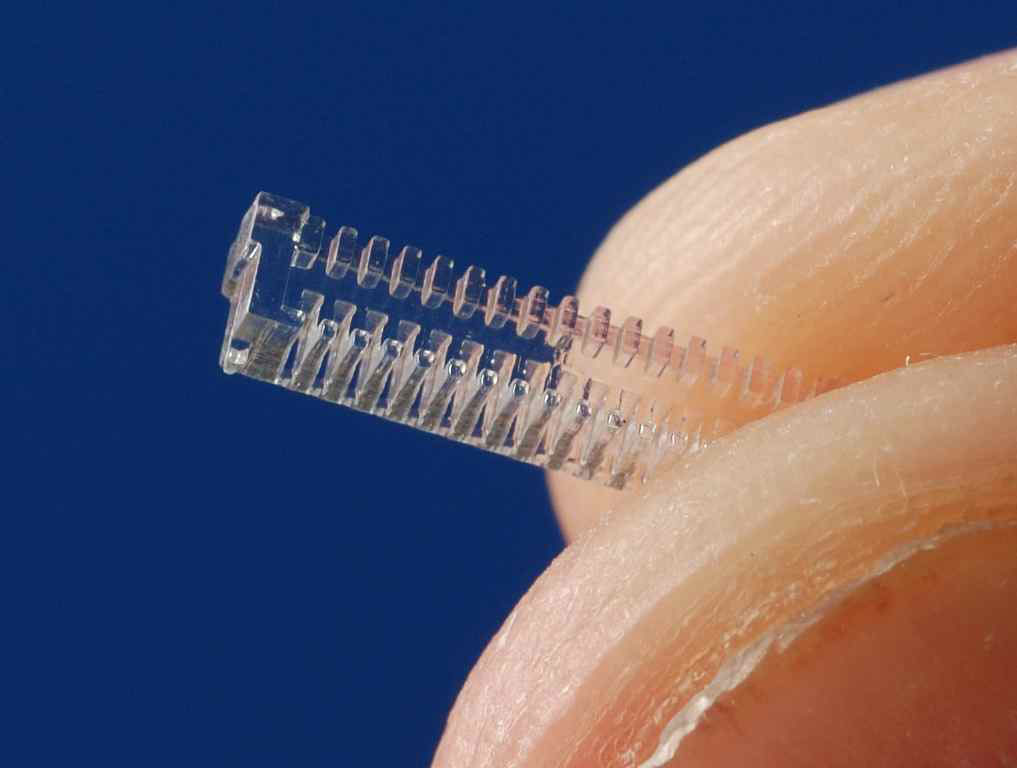

High Resolution Stereolithography (Hi-Res)

Sometimes known as ‘small spot’, High Resolution Stereolithography (Hi-Res) is typically used on smaller parts that are feature rich or where high accuracy is required.

Sometimes known as ‘small spot’, High Resolution Stereolithography (Hi-Res) is typically used on smaller parts that are feature rich or where high accuracy is required.

It uses a finer layer thickness and more tightly focused laser beam than conventional Stereolithography (SLA), which can result in longer build times.

Multiple materials are available depending on the application, some of which may be thermally post-cured to provide better temperature resistance.

Micro Options

For those situations where high resolution is just not enough, take a look at our fine layer resolution process here or alternatively you can find more information on our 3D Printing page.

Plunkett Associates know it is imperatitve to choose the correct material for Stereolithography (SLA) in order to get the best results. With regular access to a large range of the latest resins and advanced processing platforms, we can ensure that you make the right choice for your prototype part.

The following articles provide useful additional information:

‘What is the difference between SLA and SLS?’ and ‘Should I use SLS or SLA for a functional prototype?’

If Stereolithography (SLA) would help to advance your project, or you are unsure about which process to use, please contact us.

“Plunkett Associates truely offer a complete turnkey solution with Speed, Effectiveness and Precision.”

David Harden, Enica Ltd