Flexible Parts

Need a part to flex in it's operation or assembly? Let's look at rubber and flexible elastomers.

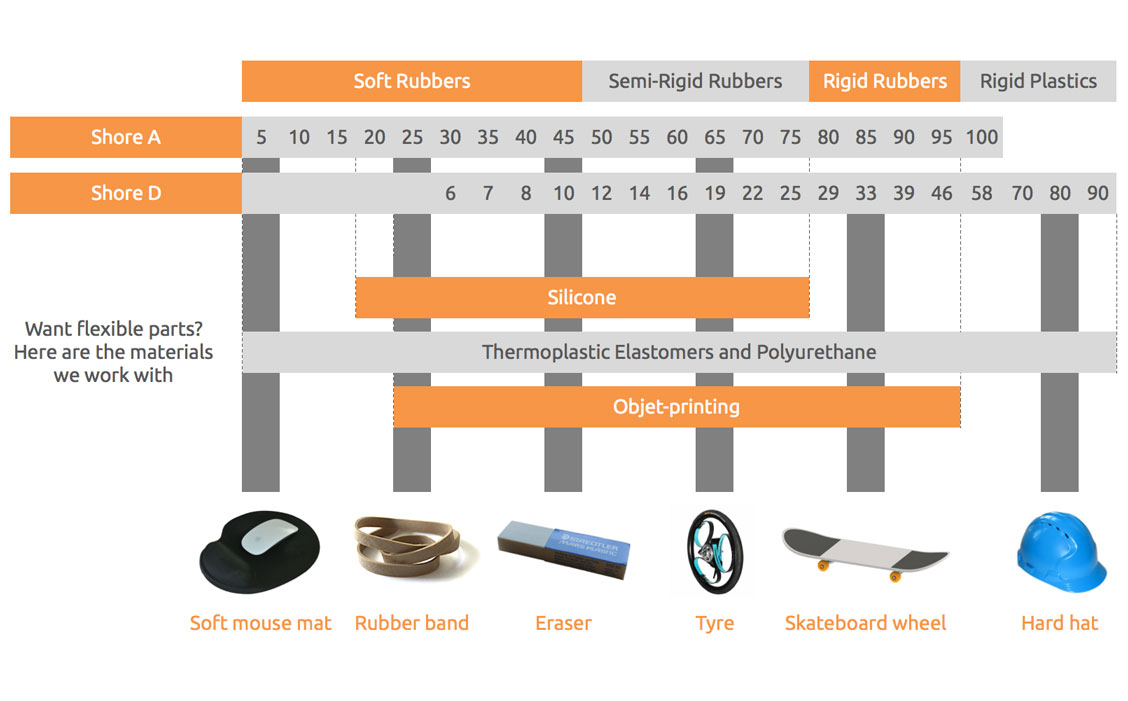

Flexible parts are often referred to colloquially as ‘rubber’ parts. Whilst rubber forms a substantial proportion of them, there are also flexible polyurethanes and thermoplastic elastomers to consider.

As an ISO 9001:2015 Quality System certified supplier, we work with all these materials, in low volume quantities of just a few parts through to full production, and in a range of Shore hardness.

As an ISO 9001:2015 Quality System certified supplier, we work with all these materials, in low volume quantities of just a few parts through to full production, and in a range of Shore hardness.

Prototyping flexible parts

The advantage of prototyping parts designed from rubber or flexible elastomers such as silicone, is that it enables you to confirm the required rigidity of the material before committing to production tooling. However, prototyping flexible parts can be a challenge!

The quickest option is to 3D print “rubber” or other flexible parts, however whilst they may demonstrate a level of elongation in a variety of harnesses’, their properties fall well short of production intent materials and little can be done to improve the layered surface finish. (Note, flexibility can be achieved through additive techniques but tear strength, chemical resistance and elongation to break will be significantly reduced).

Vacuum Casting can offer a better solution, and can produce custom flexible parts in an elastomeric polyurethane. This can provide prototype options of Shore A hardness’ ranging from 15 (simulating soft rubber) to 95 (simulating hard rubber). Surface finish is dictated by the silicone tooling and aesthetically pleasing parts can be produced.

Vacuum Casting can offer a better solution, and can produce custom flexible parts in an elastomeric polyurethane. This can provide prototype options of Shore A hardness’ ranging from 15 (simulating soft rubber) to 95 (simulating hard rubber). Surface finish is dictated by the silicone tooling and aesthetically pleasing parts can be produced.

However neither of these options will truly emulate a production TPE or rubber, especially in areas such as elongation, temperature resistance or stiction.

Production Options

If higher volume quantities are required, tooling will be a requirement. A large range of rubbers including silicone, nitrile, neoprene, EPDM and Viton can be moulded in compression tooling. This is relatively simple compared to injection mould tooling and multiple cavities can be used to offset longer cycle times.

In contrast TPE’s require tooling designed and manufactured to injection moulding standards. Material is processed and injected in the same way as ABS or PC would be for rigid parts. It is more sophisticated than compression mould tooling and as a result more expensive.

Thus for a low call off of say 100 parts per year, the lower tool cost and greater cycle time of compression moulding is unlikely to be an issue. As the quantities rise, the number of cavities in a tool can be increased, so a ten, twenty or more cavity tool is possible (geometry permitting).

However, ultimately the additional expense of injection mould tooling and faster cycle time will pay off, and needs to be considered.

To find out more about process options for rubber prototyping and production parts talk to us today. We will be happy to discuss your project with you.

Shore Hardness comparisons can be seen in the chart below. Some of our FAQ’s we’ve included about flexible materials, custom rubber parts and Shore hardness may be useful too.