Direct Metal Laser Sintering (DMLS)

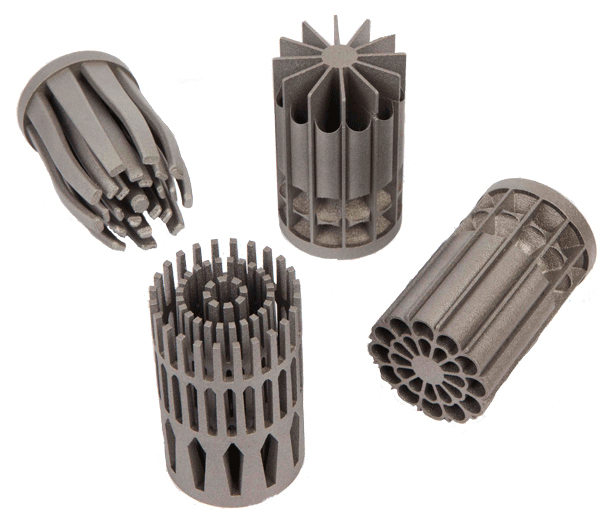

DMLS (or Laser Cusing) is an additive process, suitable for prototyping & manufacturing of metal parts with highly complex or feature rich designs.

Functional prototypes and low volume production parts

DMLS is rapidly gaining long overdue acceptance and credibility due to it’s ability to produce highly complex, accurate parts in a competitive time frame. Consequently, metal sintering is often used to produce complicated functional prototypes and low volume production parts.

The DMLS process is similar to the laser sintering of plastics, but works with a variety of metal powders. Parts are constructed additively, sintering powdered metal one layer at a time using a powerful fiber optic laser. As a result, strong, durable metal parts are produced directly from 3D CAD data without the need for tooling.

We are currently able to produce DMLS parts in maraging steel, 17-4 SS, 316L SS, cobalt chrome, aluminium, titanium and inconel.

Plunkett Associates have been using DMLS for many years as a tool particularly within the medical and dental sectors, as well as defense, aerospace and automotive industries.

Ideal for small, highly complex, accurate parts

Costs are defined by the size of the part rather than the complexity, therefore metal sintering is ideal for small prototypes or production parts which require geometries that cannot be manufactured by other methods. Features such as complex channels and other internal geometries; parts within parts, such as interlinking chains, can all be manufactured through our DMLS service.

Timescales are around the 2 week mark. However, bear in mind, that issues such as required tolerances and surface finish impact orientation, and thus it is advantageous to supply a control drawing with the CAD data to ensure no production delays. It may be worth looking at our article, What surface finish options are there for DMLS parts?

There are limitations to be aware of, slow build speed, restriction of build volumes to 250 x 250 x 150mm (although bigger machines are on the way), and the fact that support structures are required. Unlike Stereolithography (SLA) these can be difficult to remove and require the geometry to permit access.

Part geometry must be designed for the process

To really extract the benefit from metal sintering, the part geometry needs to be designed with the process in mind, and not transplanted from another manufacturing technique. However, unless DMLS is being viewed as a production technique (RM), this is seldom the case, and compromises are required.

This is where Plunkett Associates knowledge and experience can help. We can help with either DMLS prototyping or production. Plus we have relevent in house software, which lets us analyse geometry for optimal results. Out article CNC versus DMLS may help too.

We can help you optimise your DMLS parts, so get in touch today!

“Thanks to Plunkett Associates flexible, bespoke and cost effective service I was able to produce the objects I had in mind”

Simon Ryder, Artist