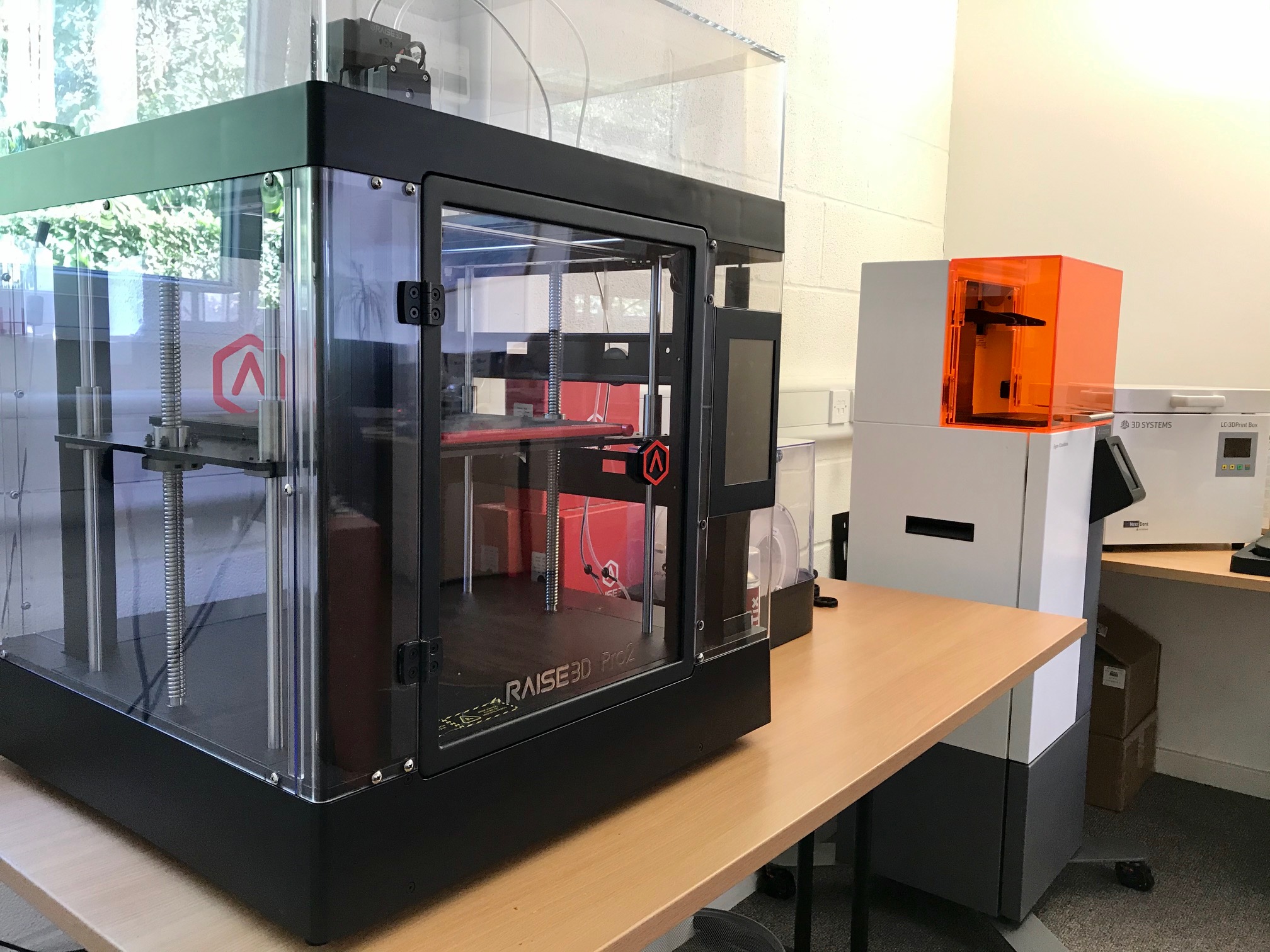

Digital Light Printing (DLP)

Digital Light Printing (DLP) is a form of 3D Printing that is extremely quick and accurate!

What can DLP do for me?

Digital Light Printing (DLP) is a form of 3D Printing that is extremely quick! It also combines a high degree of accuracy that satisfies most design requirements with a huge range of materials.

Numerous prototype iterations can be produced together or sequentially, providing visual and tactile feedback and enhancing the design process.

DLP can provide parts that range from simple physical models to parts used for functional testing and even production ready, end-use parts.

What size parts can I build?

The Figure 4 has a build envelope of 124 x 70 x 198 mm, perfect for small to medium sized detailed parts.

Range of materials

A diverse selection of high-performance materials can be used, including those with fire retardancy, high temperature resistance, or materials that closely replicate ABS or Polypropylene properties to name just a few.

Some materials can be sterilised and are even bio-compatible, a perfect fit for the medical industry.

Often used as a metal substitute, we’ve printed pins, bushes, brackets and clips in the fraction of the lead-time of a machined part but with all the required properties.

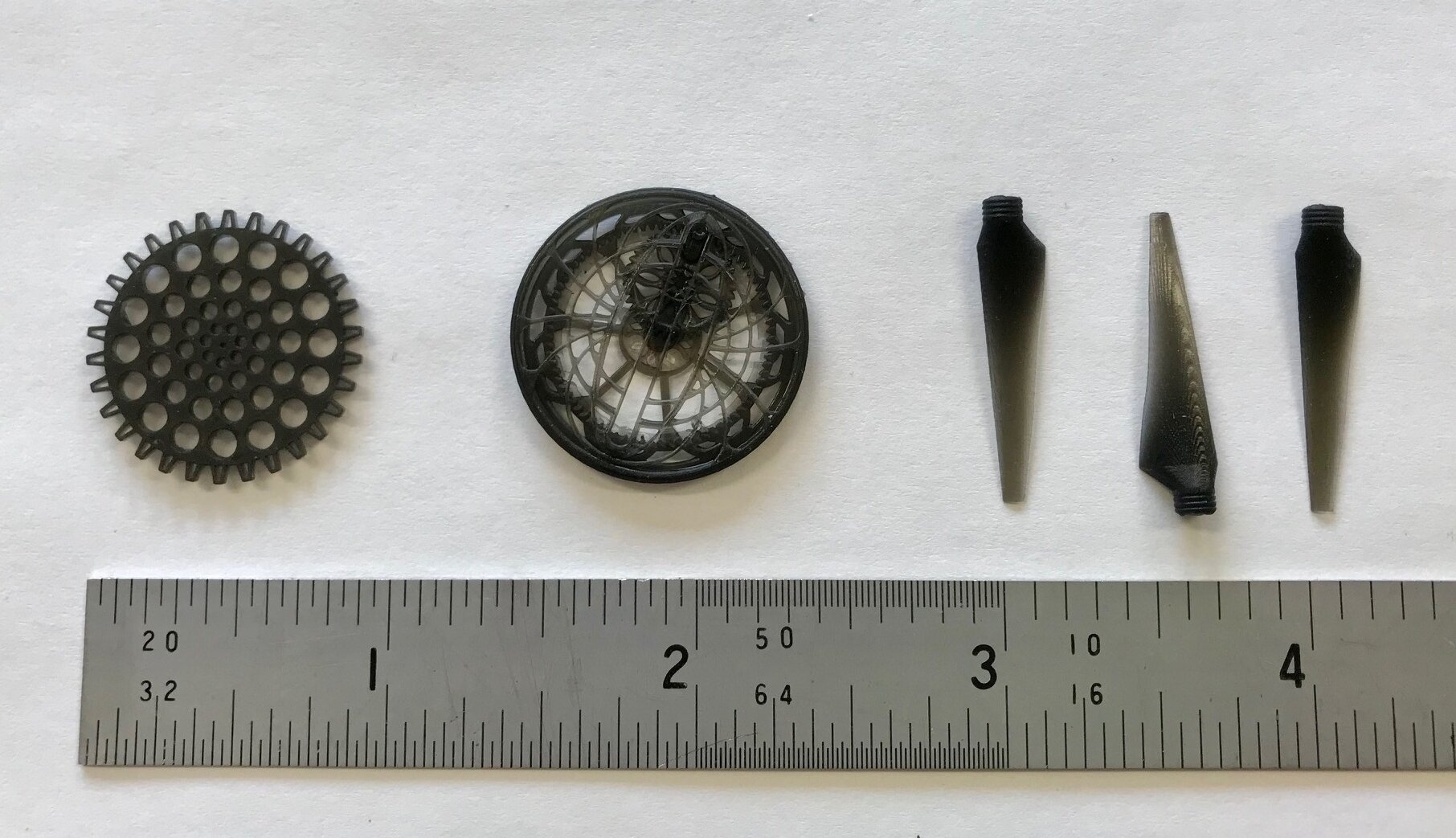

Micro resin-based parts

For those situations where high resolution is just not enough, we offer a fine resolution process operating from 50 micron all the way down to 10 micron layers, perfect for smaller parts that are feature rich or where high accuracy is required.

With a range of materials and colours plus a 24 hour turnaround service, this provides an easy fast track option for micro resin-based prototype or production parts.

How quickly can I receive my parts?

The simple answer is, it is possible for parts to be shipped the same day we receive your data (depending on geometry and availability of course!) which brings huge advantages when projects are under tight timelines or need multiple design reiterations tried and tested.

With 30 years’ experience of professional prototyping with a focus on technical expertise and customer service, Plunkett Associates provides early conceptual prototyping services followed by full production options with tooling and moulding capabilities if required.

For further information please contact us today for unbiased professional advice.

“It’s great to work with a supplier that doesn’t have minimum order quantities and gives the same detailed attention to every job.”