Injection Moulding

Produces production intent material properties. Injection Moulding is used for development as well as production parts.

Injection Moulding is a recognised production technology often dismissed as being associated with high production volumes, long lead-times and somewhat inflexible. This, however, is not always the case.

Once tooling is in place, parts are available quickly at low cost

Once tooling is in place, parts are available quickly at low cost

Injection moulding depends on the number of parts you need and their geometry, but it does offer an option where you can economically have additional parts without a high premium. It delivers the production intent material and, once the tooling is in place, parts are available quickly and at low cost.

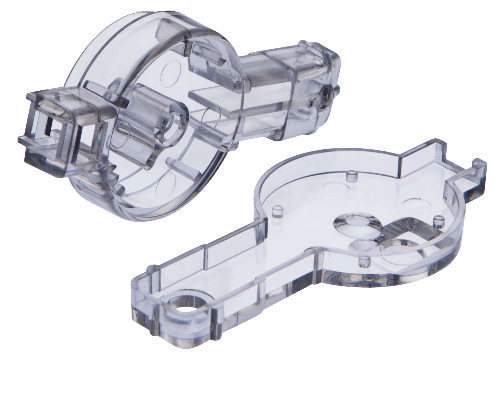

Commonly used materials used are ABS (Acrylonitrile-Butadiens-Styrene), PA (Nylon), PC (Polycarbonate), PP (Polypropylene) and GPPS (Polystyrene). We can help advise on material selection depending on your requirements.

Additionally PVC (polyvinyl chloride) is a highly versatile, incredibly cost effective material that is often overlooked. It is strong, durable and lightweight as well as being an extremely safe material being non-toxic and fire resistant. PVC parts are consistent in terms of surface finish, will retain their colour and don’t tend to fade like some other materials.

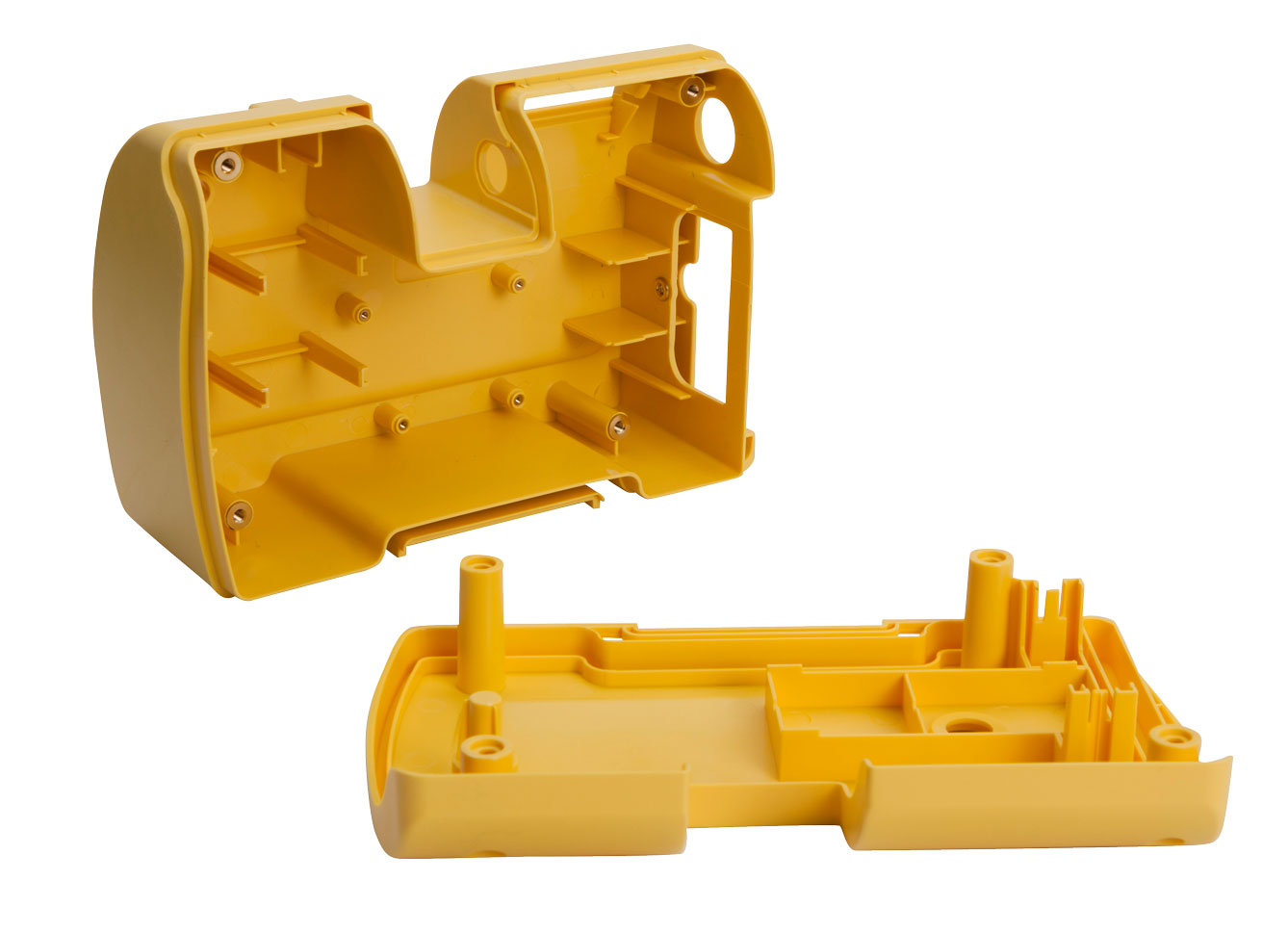

No limitations to part complexity

In addition there are no limitations regarding the complexity of the parts that can be produced. The sky really is the limit…

Since early 2000 there has been an increasing supply of ‘rapid tools’, also known as Bridge Tooling (some produced using additive technologies like DMLS and others machined from aluminium and steel). Whilst some of these tools have the potential to meet production quantities, their primary focus is high volume prototyping.

Moldflow helps us to identify potential design issues ahead of tool design

At the front end, injection moulding quotes don’t take any longer than prototyping quotes to produce and in-house analysis with Moldflow helps us to identify potential design issues ahead of tool design. Moulding parts as a single batch can save multiple set-ups and reduce lead time further. A well thought out control drawing can allow the part to be checked on press at first trial (T1), permitting the immediate production of the first batch.

We can now consider Injection Moulding as a prototyping solution with the ability to address cosmetic requirements or as a low volume production tool.

In considering it as a prototyping solution, there are many factors that have to be addressed and many alternatives that must be considered – see our 10 Top Tips…

The most important issue to consider is whether the production intent material is really a requirement. If it is, then understanding the available time and attention to the CAD model are both paramount.

Consider Injection Moulding for prototyping or low volume production

Speed is the major driver behind Bridge Tooling and first trial (T1) is frequently achieved around 15 days after starting.

Far Eastern tooling in the past has provided a source of ‘lower cost’ tools, however, tooling costs in the Far East are now rising due to higher wage expectations, increased shipping costs alongside falling exchange rates. One option many companies are looking into is to bring their tools back to the UK. As a result we are finding an increase in demand for more local ‘home based’ tooling.

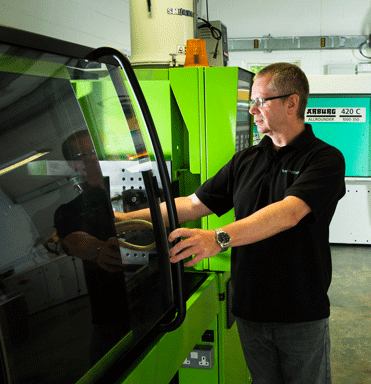

UK Moulding and Tooling Services

Plunkett Associates sister company, Adept Precsion, based in Gloucester, offers a range of injection moulding and tooling services. Manufacturing tooling in aluminium and steel, with qualified, highly skilled Toolmakers and Moulders, they will match your requirement with the appropriate tooling in order to deliver a viable moulded solution.

Additional questions are addressed in our Tooling and Moulding FAQ section.

Plunkett Associates has a track record of optimising tooling solutions to meet customer requirements. Look at case studies of injection moulding work in our examples pages, or get in touch to talk to us about your requirement.

“I can’t recommend Tim and his team highly enough. We ended up with a design which can be produced and assembled quickly, efficiently and reliably, in volumes that make sense.”

Simon Leggett, Olivewood Technology