Is Short Run Injection Moulding Expensive?

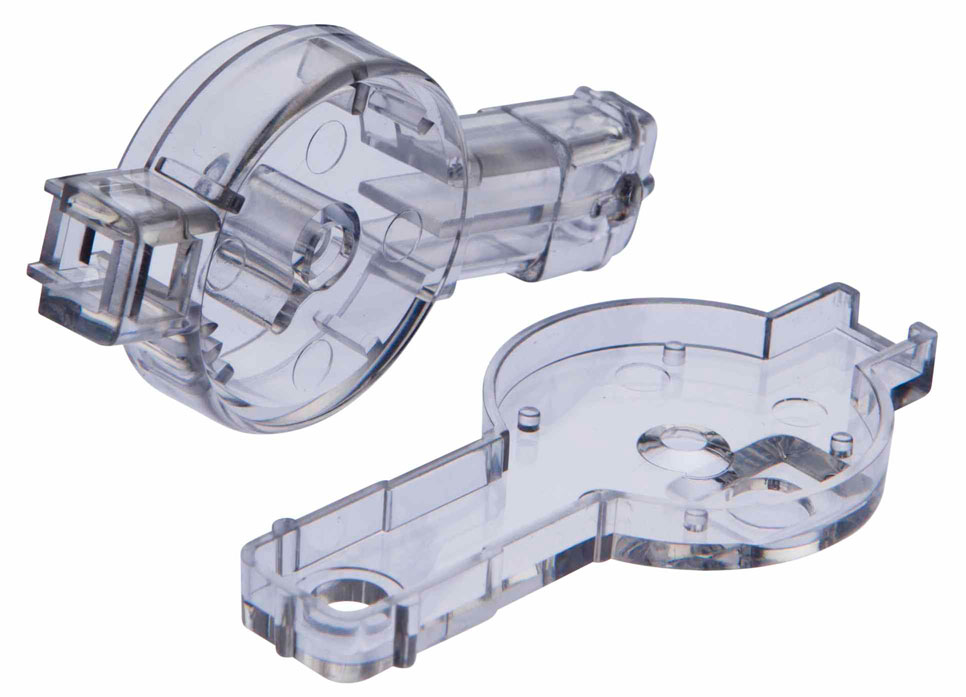

We are surrounded by injection moulded parts in every facet of our lives, from light switches to the electric kettles we use to the keys on our keyboards. The one thing all these items have in common is that they are produced in high numbers, frequently hundreds of thousands upwards.

Huge flexibility, large range of materials and cheap parts

Moulding is ideal for these requirements; with cycle times measured in seconds and part costs measured in pence allowing for the product pricing that we all take for granted. Add to this flexibility, potential materials stretching from soft elastomerics to metal replacement polymers and the scope begins to become apparent.

What if I don't want so many parts though? Then tooling must be considered. Tooling is traditionally expensive, and takes a long time to produce. That said it is the ‘enabler’ that permits the benefits identified earlier and the good news is, these days there are numerous alternative tooling options that can be considered to make the costs less inhibitive.

So what drives the cost?

Setup/cleandown

This typically includes installing the tool into the moulding press, drying and loading the specified material/colour, setting up the moulding conditions and running initial QA samples for approval. Then at the end of the moulding run purging out any residual material, applying any protection to the tooling before stripping it out of the press and returning it to stores.

This process is obviously independent of how many parts are produced and often quoted as a ‘setup’ charge, especially if dealing with low volumes. It can take anything from an hour to half a day depending on a number of factors like the size of the tool, configuration, what material/colour options are being changed and inspection/dimensional requirements.

Moulding

Moulding

The moulding phase is driven by material costs, press costs and whether the press is running manned or unmanned.

Material costs vary substantially from one material to another, and also depend heavily on the quantity being procured. For example it is quite possible to see a 10:1 difference in price between buying a single 25kg sack and 3 tonnes of material.

Colours can require masterbatch or compounding and add further to the costs especially if universal grades cannot be used.

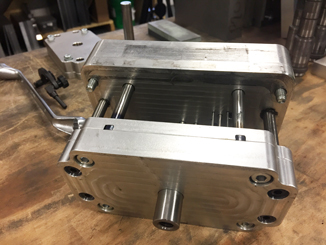

Press size is a function of tonnage (force required to hold the mould tool closed during the injection cycle) and shot weight (amount of plastic delivered to the mould per cycle). The larger the press the more expensive it is both in terms of depreciation and power to operate.

Whether a press is run manned or unmanned is more often dictated by the tooling rather than the press. With small batches, lose inserts may be used requiring an operator to load and unload the inserts every cycle. Alternatively there may be a post moulding operation that is completed by the operator (or robotic alternative) whilst running the mould – this could be printing or packing.

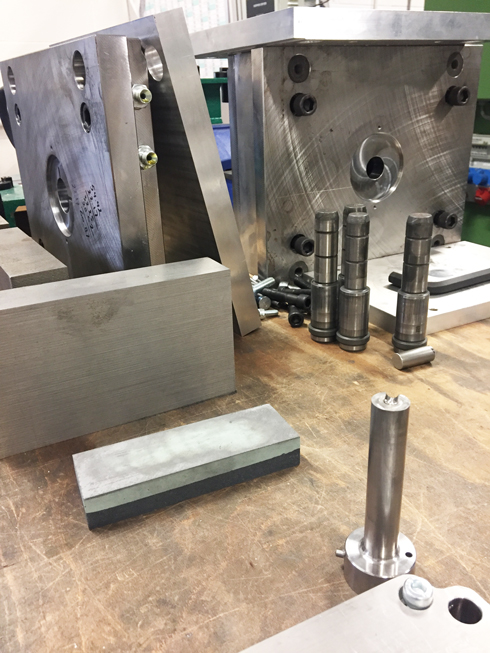

Tooling

Tooling

Tooling costs will vary dramatically depending on the specification. It is not just the tool cost that is important, but matching it to the quantities required and deciding how to account for the cost. Getting this right and aligned to the production quantities is vital.

Different companies account for tooling in different ways and thus it shows up in the unit price differently:

- Company A might choose to write off all tooling costs in the development phase, thus giving production a ‘free’ mould.

- Company B might predict the product life and write the tool off against parts produced, effectively wrapping an element of the tool price into every part, or

- Company C could treat the tooling as an asset and follow its own depreciation schedule.

All will give different results. However, whichever option is employed it can be seen that there is a dramatic difference between:

- a fully automatic tool, possibly with multiple cavities, running 24/7 on a press producing a quarter of a million parts per month, and

- setting a tool to produce 200 parts using lose inserts with an operator manually packing each one.

Are there prototyping options?

Most definitely, yes! The ability to have prototypes in the production intent material is a huge driver. Nowadays we get involved in moulding as few as 2 parts, we have multiple tooling options at our disposal both to advance prototyping and also tackle low volume production.

Development Tooling and moulding parts can be produced in a few days, but this will be subject to a string of conditions relating to the geometry, material, finishes etc.

Quoted times will only apply to T1 (first trial), so any tweaks will increase the lead-time. More typical timescales would be around 2 – 4 weeks.

Tool costs

Costs are driven by part complexity, size and time. It is unusual to see any mould tool offered for less than £2,000 and in this case the parts may well carry a substantial premium.

A wide variety of tools could be produced for £5,000 – £7,000, although large complex items can see this exceed £30,000. The only way to accurately quantify this is to obtain a quotation against the specific data involved.

Additional information on the different types of tooling and options to reduce both the cost and associated lead-time for low quantities can be found here.

We are specialists in low volumes, so if you are considering injection moulding for your project but are unsure of the potential price point for your quantities, please contact us. We will be happy to advise.