How many parts can I expect from an aluminium tool?

The two big factors here are the grade of aluminium used for the tooling and the material being moulded.

The two big factors here are the grade of aluminium used for the tooling and the material being moulded.

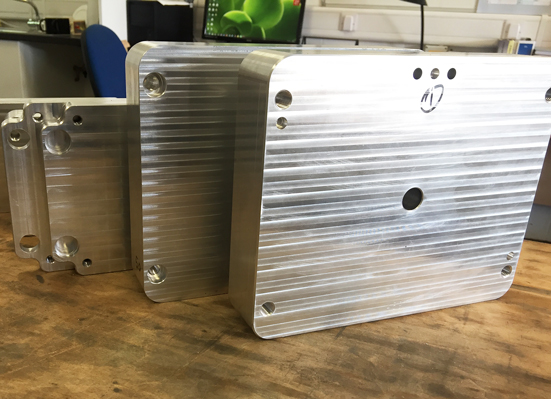

Differing grades of aluminium offer improved hardness

Depending on the source, different aluminium grades may be used from relatively soft 5000 series through to grades specifically developed for moulding, such as Alumec, that offer improved hardness, machinability and strength.

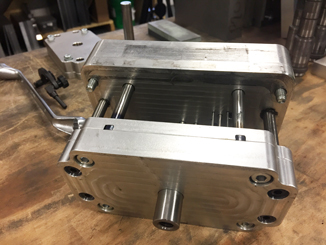

Aluminium tooling will be ‘softer’ than steel tooling, and as such material fillers such as glass will result in increased levels of wear. Whether this is a problem will be dictated by the tool life specified. Development or Bridge tooling is inherently looking to produce limited numbers and as such, so long as suitable aluminium is used, wear is unlikely to be an issue. If greater numbers apply, for example when aluminium tooling is used to service a production solution, making components such as the gate as a steel insert will improve tool life.

Tool life from 1000 up to 100,000

In summary, correct selection of aluminium will give a tool life of 1000’s in the vast majority of moulding materials, filled or not. Well designed aluminium tooling can be good for a hundred thousand parts in unfilled materials.

Contact Us if you have a requirement for aluminium tooling, we have experienced, specialist toolmakers both in the UK and the Far East, supporting both prototyping and production tooling needs.

See our sister company, Adept Precision, for more information on aluminium tooling.

Associated pages: