How do I make the transition from prototyping to production?

3D printing has unleashed the inventor in many of us, both as individuals and within the companies we work for. Now it is possible to realise an idea physically, at a price point that gives everyone access. When combined with the ‘almost’ unlimited geometric freedom that goes with 3D printing, it is clear as to why this is being heralded as the next industrial revolution. The only problem is that it’s not that straightforward!

Quantities are key

For particular geometries, designed to undisclosed rules, 3D printing can remain competitive for many more than the usual 1 – 10 type prototype requirement. Ignore the rules and costs quickly spiral.

This makes the transition from first off, to a part that can be manufactured in quantities at an acceptable price point, somewhat more of a challenge and a wreckers reef for new ideas.

Tim Plunkett, Director of Plunkett Associates explains,

“Having spent the last 25 years in what is now termed 3D printing, we have seen the benefits this can bring. Unfortunately these same benefits can work against you when it comes to moving to production. The design freedoms suddenly evaporate and there are new sets of rules to abide by. This is why Plunkett Associates is here, to help with the transformation from prototype into production.”

Design for the process

We work with a huge range of processes to ensure that the optimum solution is found and that the design addresses the strength of the process, rather than being at odds with it. Quantities are key to getting this right and whilst they may change across the life of a project, they form a vital step in making the correct process decisions.

Many processes are associated with a range of quantities that can be driven as much by the desire of the company offering the service as they can by the capability or economics of the process. A prime example being injection moulding, where it is often the moulder who establishes the minimum number of parts he/she is prepared to run in a batch. This can be linked to staffing ratios as much as economics.

Thus establishing a network of suppliers who are prepared to go outside of the norm, creates a high level of flexibility. When we combine this with a design that is optimised for that process, we create a whole host of new opportunities.

Looking at plastics

When we consider the options for plastics, we expect to look to 3D printing or additive manufacturing processes such as SLA, FDM and SLS, particularly for prototypes. However, CNC prototypes have a lot to offer, especially if the goal involves aesthetics. CNC machining can be cost competitive, frequently allowing a ‘finished’ part to be delivered for the same price as a ‘raw’ 3D printed part. Depending on numbers required for production an added advantage is that this process may be used for both phases as a viable cost effective solution and offer ‘real’ material properties.

Looking for metal parts?

From a production perspective, most metal parts are designed for either CNC machining, casting or die casting, although as the capability of DMLS continues to improve we are starting to see some items designed especially to take advantage of additive manufacture.

The early assumptions with additive metal processes were that it would short cut prototype times. However the reality is that these processes are qualifying for production much faster than was originally expected. The result is that it is frequently faster to CNC machine a one off prototype than to use DMLS, geometry permitting.

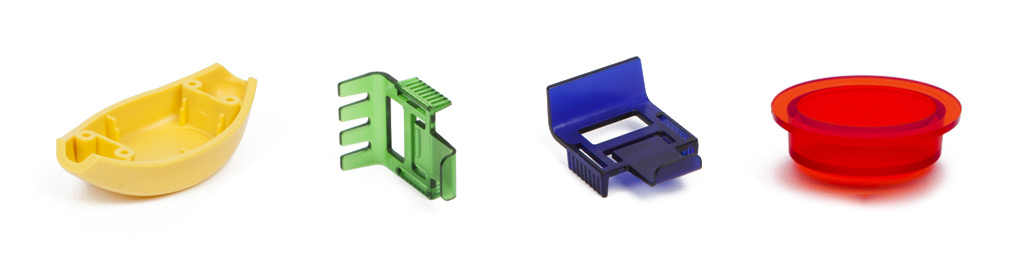

Clear parts that look spectacular

When we look at clear parts, additive techniques, CNC machining, vacuum casting or injection moulding can all be considered. Each process offers particular advantages depending on quality requirements, leadtimes and economics.

If the geometry and quantities are suitable, hand polishing combined with CNC machining, using materials such as Acrylic (PMMA) or Polycarbonate (PC) will generate spectacular results.

As quantities rise however, it becomes necessary to avoid hand polishing and use other manufacturing methods such as low volume injection moulding. Once the tooling is in place it is easy to make 50, 1000 or even 10,000 parts.

Prototyping flexible parts can be a challenge

Prototyping flexible parts can bring other challenges. Whilst it is possible to 3D print materials that demonstrate a level of elongation in a variety of harnesses’, their properties fall well short of production intent materials. Vacuum Casting can offer a better solution, although is more costly.

Neither of these options, however, will truly emulate a production material like TPE or rubber. If the purpose requires functionality, then either compression or injection tooling is usually required. The upside is it comes with a huge range of material options!

Plunkett Associates are specialists in prototyping and production, but probably most importantly, getting from one to the other. We are here to help and are, as ever, at your service.