How can I make sure the data for my part is correct?

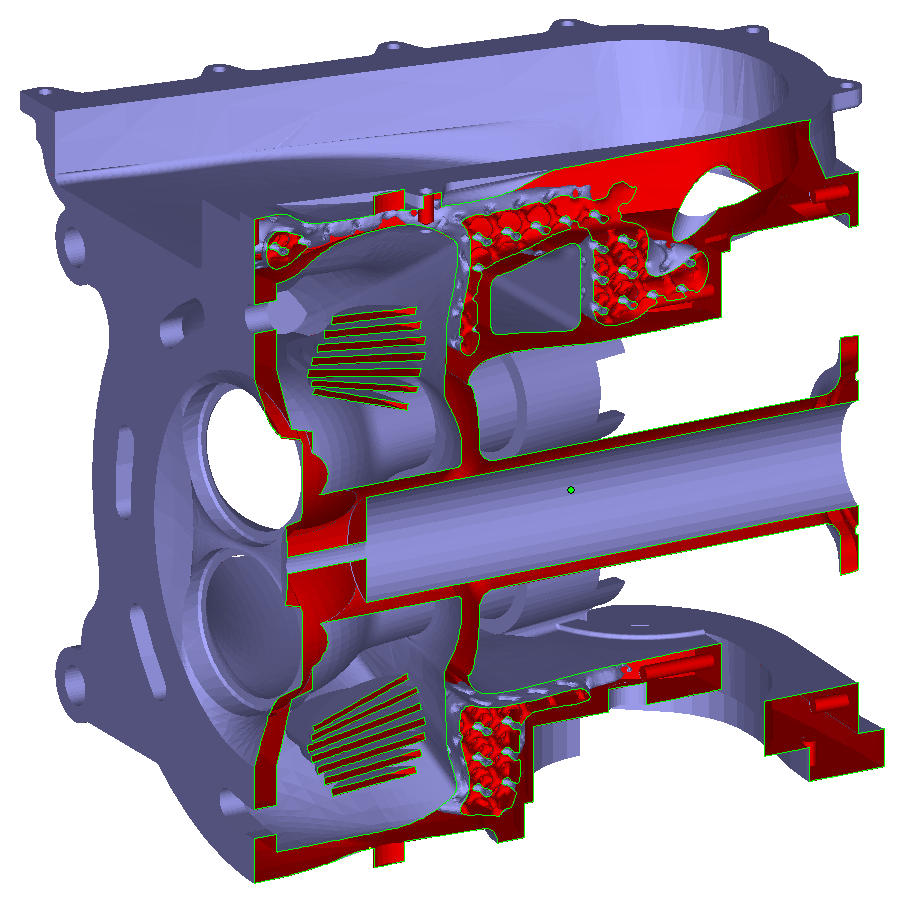

All manufacturing that we undertake utilises the 3D data supplied by the client, or is generated by ourselves if design is part of the service.

As such, ensuring that the parts go together and have been modelled at the correct tolerance, is as important as ensuring the tolerances are achievable by the process employed.

Check, check and check again…

Check, check and check again…

The ever increasing functionality of today's software is a great help here, but the old adage of check, check and check again remains very applicable.

The earlier in your project we can be involved, means we can take away some of your headaches and help make this critical part of your project go as smoothly as possible. This is often the point at which time, and therefore money, can be saved later on down the line.

As we have progressed from the days of paper drawings to the use of a single data set that holds the design information and is used directly for manufacture, so our reliance on the accuracy of this information has also increased.

The number of checks that used to exist in the progression to manufacture has decreased, whilst the consequences of the data being wrong have increased, compounded by the expectation of ever shorter timescales.

At Plunkett Associates we have qualified, experienced Design Engineers who are experts in their role and who are 'old hands' at checking, double-checking and triple checking data for just this purpose. We use our knowledge and expertise to adapt as necessary until we reach a solution that works best for your requirements. Feel assured we have been there, seen it and seen it again!

What can be done to minimise the risk of incorrect data?

So, what can be done to minimise the risk of incorrect data? Obviously there are multiple software programs that will check data and predict how it will present itself as a physical part as we’ve previously discussed, but on top of this, nothing beats a bit of good old fashioned common sense! So take a step back, take a good look at your data and think about it…

- Check the tapping diameters against the thread call outs.

- On blind holes with threads, is the hole depth adequate to give the necessary full thread form and allow for the tap run-out (also on male threads approaching a shoulder)?

- If threaded inserts are to be fitted, is there sufficient wall section for the material chosen?

- If parts are being cnc machined then can the fillet radii be achieved at the required depths and if not, will the parts interfere?

- Are any critical tolerances called out on supportive drawings and are these achievable with the manufacturing process?

- Have parts been modeled to mid tolerance?

- Have fits been called out on critical mating features?

- Will the parts assemble on adverse tolerances?

- Has the data read in correctly, is the model “water tight”?

- If it is a Solidworks native file are there any suppressed features and is this correct?

- If the part is to be moulded, are the wall sections consistent and thick sections addressed?

Experience and years of practice!

As you can see, the list can go on forever! Experience and years of practice help us know potential pitfalls and what to look out for.

Remember, the earlier you call us and, the more we can add value to your project through comprehensive data optimisation. We are here to help and can ensure a well thought out, workable manufacturing solution for your project.