When is Stereolithography the better option?

Many years ago, Stereolithography (SLA) was the rapid prototyping solution, accurate, fast, relatively stable unless you can remember the acrylic based resins, and easy to paint. It was the dream master pattern for the vacuum casting process and could even be used as an investment casting pattern.

Then along came laser sintering (SLS), worse surface finish, less accurate (usually), often slower due to the required cool down times (or it warped!), a real pain to use in vacuum casting and totally the wrong material to go anywhere near investment casting. (You had to run polystyrene to do this)

Come up to date and whereas the request was “please quote SLA” the most common request we hear today is “please quote SLS”, so what happened and are people missing out?

SLS provides functionality testing

What SLS brought to the game was a level of functionality that an SLA user could only dream about, working predominantly in Nylon 12 these parts could take some serious abuse. In fact, so much abuse that we were constantly trying to come up with ways to demonstrate the potential. We dropped them, we parked my car on some, and then we built panels for a Smart car and drove it around. Up to this point the only alternative would have been to use a Stereolithography master and vacuum cast it in polyurethane, a combination that would have doubled the lead time. Against this the negatives were insignificant; parts could now be used.

Of course, the other differences were no supports and a consequence of this, the ability to pack parts in three dimensions rather than two. Both of these offered a potential economic advantage that led to SLS being generally regarded as the most cost-effective prototyping option.

So, given functionality and a better price why is Stereolithography still around? Well for vacuum casting that is easy to answer, the finish is far better suited to moulding form. For prototypes the clue is in the materials, these have not stood still, and whilst there may be a general acceptance that Nylon 12 will out function Stereolithography resins, there is another objective hidden here and that is one of simulation.

SLA produces accurate parts with an excellent surface finish

It remains that a massive reason to prototype is to confirm the design integrity before going to tooling, a high value long lead item that can be compromised by changes. To achieve this accuracy is clearly important, but so are the tactile senses – does it look and feel right? This is why in resin marketing we see phrases like “the look and feel of an injection moulding”.

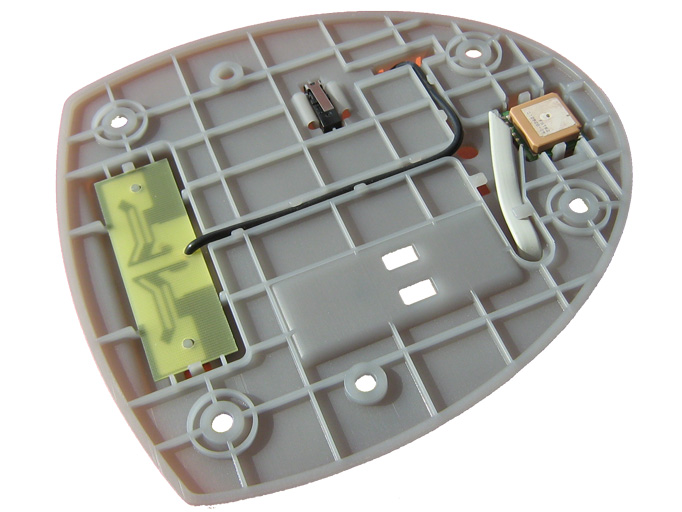

This creates a different objective, that Stereolithography is well placed to fulfil. This is about simulating injection mouldings, about accuracy, appearance and yes functionality but only to a threshold and not absolute. Mouldings utilise snap fits and self-tapping screws for example and clearly these must also work. We have to be able to handle and assemble the parts without fear of breakage too, but is it necessary to drop it on the floor? If the material is not the production material what is this going to tell us?

The logical follow on question is “well what if it was the production material?” With the ever-increasing process speed this is starting to happen, material properties are there for some applications and will no doubt continue to progress. There is also much work going into post processing of all additive parts, methods of colouring and improving the surface finish of SLS being some of the most dramatic.

Economics and price

The other issue was economics or price, and this brings some surprises, SLS is not always the cheaper option. This is geometry and resin specific but there are increasing cases of Stereolithography offering a very competitive price point to SLS.

There is no ‘one answer fits all’ but in this particular tussle its worth stopping to ask, ‘what am I really trying to achieve’ and at least explore the options. There are other processes out there that also deserve consideration and the optimum choice will only come from a wide understanding of the pros and cons of each, for example, where should DLS or FDM fit in this?

Understanding your objectives

It is for this reason that Plunkett Associates will often ask for more information, to try and better understand your objectives rather than just quoting what you ask for. It’s not that we know better, it’s just that there may be another option out there!

PS Before you ask, the Stereolithograhy resin alluded to that has given us such good results is from DSM and is called Somos EvoLVe 128 – a data sheet can be found here.