Should I use SLA or SLS for my prototype?

You need a prototype, and are thinking Additive manufacturing, but just not sure whether to go Stereolithography (SLA) or Selective Laser Sintering (SLS)?

Our simple to follow, light hearted step by step guide should help give you the basics…

Q1 Toughness – what are you going to do with it?

Q1 Toughness – what are you going to do with it?

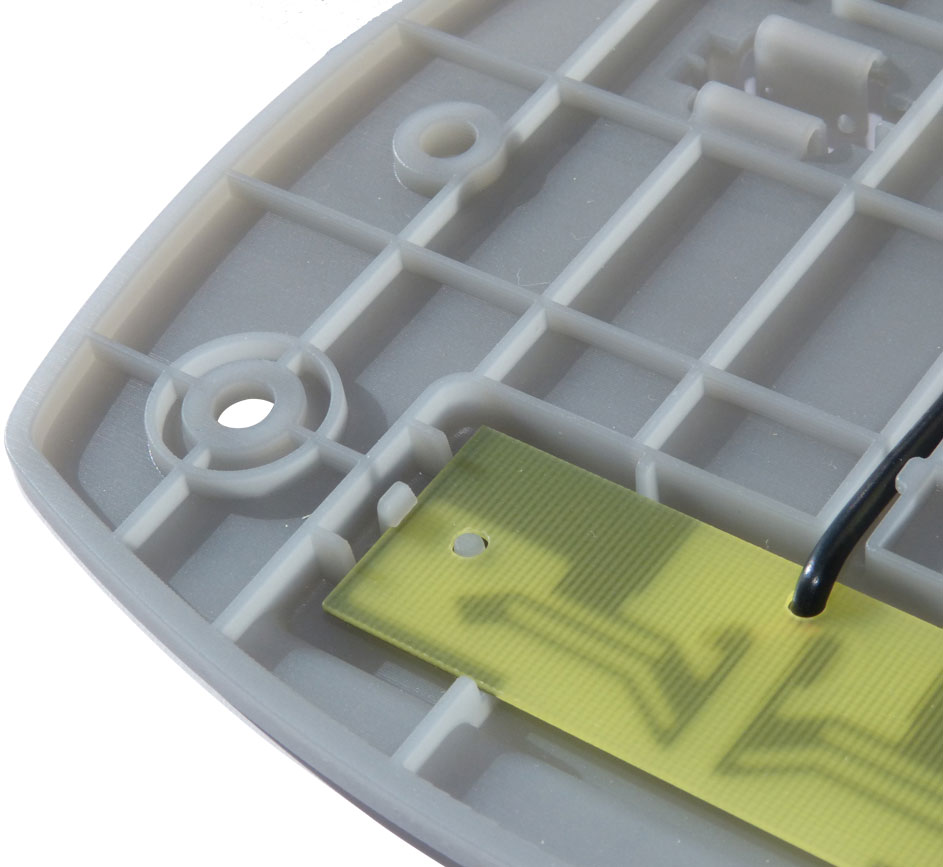

This has to be the first decider! If you are planning on throwing your part around the office and your colleagues can’t catch, then we need to be thinking SLS! Parts made by SLS are typically nylon and hence tougher than the average SLA resin.

Years ago we built a 3 – 4mm wall section, box type part in SLS and I parked my car on it, to prove a point.

SLA resins continue to improve but they are generally not in this league.

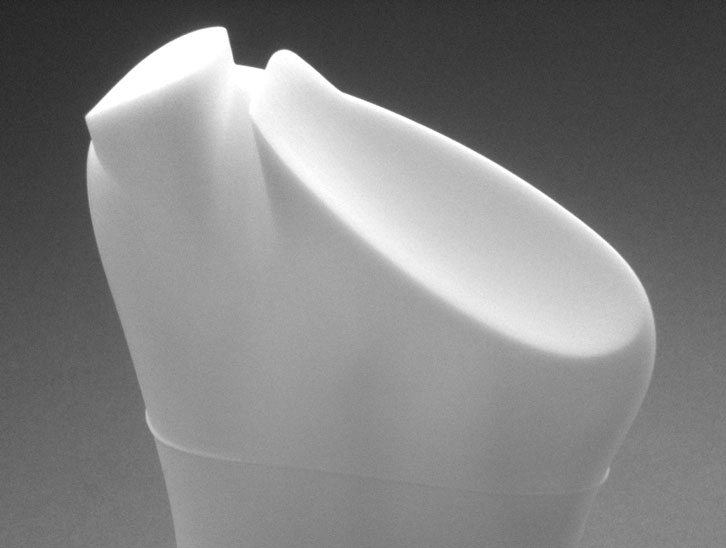

Q2 Surface finish – rough or smooth?

On the presumption that we are not going to dress the parts as this always adds cost, and surface finish is important, then you need SLA.

SLS is like a course spark finish, SLA is closer to a moulded plastic part.

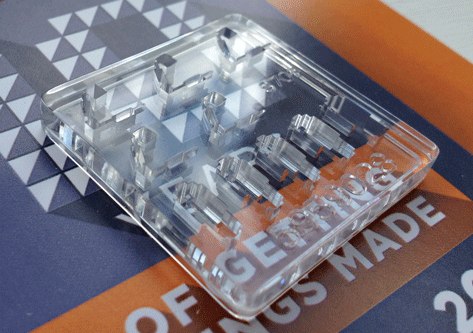

Q3 Clarity – do you need to see through it?

SLS, no chance!

SLA, some resins are translucent and some are clear. To get the clarity you will need to polish/dress the ‘as built’ part.

Q4 Flexibility – hard or floppy?

SLS will allow you to build parts that bare a resemblance to TPE/rubber, whereas SLA works with hard materials. You will not get a range of hardness options (Shore A) but sometimes anything floppy is better than something hard!

Q5 Accuracy – how accurate is accurate?

These are all generalisations, but typically my money would be on SLA giving a more accurate part than SLS. Yes it depends on machine calibration and a host of other things but if you are in to measuring fractions of a mm then you want SLA

Q6 I need something to test?

Q6 I need something to test?

This is like the proverbial bit of string! It really depends on the test.

If you are checking IPXX, then accuracy of seal groves and quality of mating surfaces will be very important, go SLA.

If you are going to bolt it on a car and do 10,000km, go SLS.

If it's a temperature test, be careful! This can get geometry specific quite quickly. Some of the specialist SLA resins are good with temperature but ultimately it's the softening point that is your key combined with the service loads. (Note I ducked that one)

If it's a desktop product, either will suffice.

Q7 Cosmetics – exhibition models?

SLS will usually take more time (hence cost) to dress to a cosmetic finish than an equivalent SLA part. Either will work, so perhaps the decider should be whether it’s going in a glass case or not!

Q8 Can I have hollow parts?

SLA requires support structures unless the part can be angled/designed to avoid them. As such access is required to remove them and this must be allowed for.

SLS uses the lose powder to perform this function, so as long as this can be shaken out there is less of a problem.

Q9 Do you need the parts yesterday or last week?

This is more about who you can find who has the capacity to do the job NOW!

SLS is a thermal process that requires the build to heat up and cool down – otherwise the parts distort like anything. However there are no supports so once cool the parts are almost instantly usable.

SLA requires supports but these can be constructed automatically and removed relatively quickly.

SLA requires supports but these can be constructed automatically and removed relatively quickly.

Possibly more importantly the economics of SLS require that the build is filled with parts, whereas SLA can run with a partial build. Hence SLS bureau's have to consolidate jobs to make the economics work.

Finally, it is possible to add parts to a running SLS build but not to an SLA build, useful if the train has just left the station…

Q10 Which do you want?

We all have a preference; sometimes instinct is the best guide!

Yes there is more, but this will point you in the right direction, if in doubt, just give us a ring or send your data to us at solutions@plunkettassociates.co.uk