What are my options if I need to manufacture Custom Electronic Enclosures?

Bringing a new product to market is challenging at the best of times. Generally the more technology involved, the longer it can take. Hence sorting out the ‘box’ to house the device frequently gets pushed down the list to “sort later”!

Before you know it, “later” arrives, you have no enclosure, no time and apparently no options. Sound familiar? Don't worry, Plunkett Associates can help. The parameters that will drive any solution are time, quantity, specification and of course, budget.

Time

Once the interface requirements and specification are known, design can take from 2 days to 4 weeks, depending on the complexity being sought, number of prototypes to be produced, validation testing etc.

With the design in place 3D printed enclosures can be available in a matter of hours, aluminium injection mould tooling in 2 – 3 weeks and even full production steel tooling in 4 – 6 weeks. Once the tooling is signed off moulding can produce 1000 plus parts a day.

Quantity

If production quantities are low and there are no specific aesthetic or material requirements, then 3D printing or vacuum casting offer potential solutions. The transition point to tooling/moulding is driven by part size and complexity but can be sub 100 parts.

Aluminium tooling will support moulding into tens of thousands of parts, and steel well in excess of this. Quantity is a factor both in batch size and in annual call off. For example 20 parts a month is 240 per annum, which if taken as a single batch could well put you in moulding territory.

Budget

Consider how realistic are the quantity projections, how long will it take to get there and what can be done to help cashflow in the short term? In reality, this could mean vacuum casting or the use of standard enclosures initially, moving to development tooling and then committing to full production tooling only when the orders are in place.

Design

Design is the key to achieving the timescales, specification and budget.

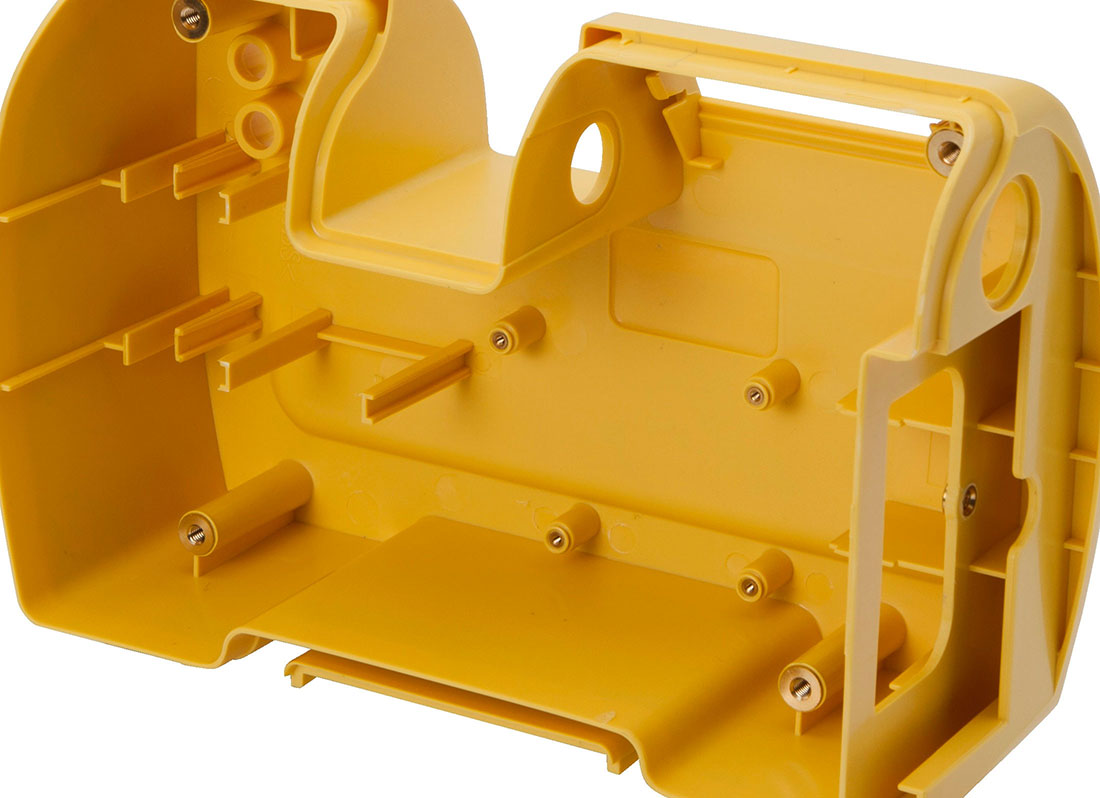

Many enclosures start life as 3D printed parts however, the technology cannot support the higher quantities economically and a transition to moulding is frequently required. If this has not been considered early on, whilst enjoying the freedoms that 3d printing allows, then it is unlikely moulding will be viable without a redesign.

The more detailed the specification the easier the job. This should determine temperature requirements, aesthetics, sealing (ingress protection), fire retardancy, interface requirements, branding to mention but a few.

Design for Manufacture

Plunkett Associates will focus on matching your design concept to the process that in turn matches your forecast quantities. Ensuring that the radii are where they need to be and not where they just incur cost, wall sections are feasible, access is possible etc etc. In this way the benefits of the process can be delivered and the downsides limited.

With options for tooling including aluminium and steel, manual or fully automatic etc etc, we will propose solutions and manage the entire process to deliver the enclosures where you want them, when you want them.

The Solution

Don’t be put off if you have no design experience, we can work from sketches, models, really anything you have, and do the design for you, so please don't hesitate to call.