What surface finish options are available for DMLS parts?

Direct Metal Laser Sintering (DMLS) is one example of what are termed powder bed systems. These machines build your parts within a ‘cake’ of metallic powder that is subsequently recycled.

The sintered components are cut away from the build platform by wire erosion and undergo a finishing operation that is dictated by the material and application.

Whilst the build process is highly automated, separating the parts from the platform and finishing them is labour intensive. Hence designing for the process can have a significant impact of the part cost, even making some parts unrealistic even for an additive process.

The benchmark in most peoples minds when considering DMLS is CNC machining. After all this has been around a lot longer and is still the most likely manufacturing method behind a metallic part picked up at random.

So comparing the two, highlights what?

The two most striking issues will be the incredible complexity that DMLS can achieve and the relatively poor surface finish.

DMLS requires supports to build a part. So there are two distinct areas on a part, upward facing surfaces and downward facing surfaces, the former always giving a better surface finish than the latter.

The following pictures give an idea of what can be achieved, but the following pointers may well help too:

a) Design has the biggest impact of all, so follow the guidelines and don't believe the “additive manufacturing can make anything” hype! (It will have a go but you will pay for it!)

b) Seal grooves and similar features will require post machining.

c) Depending on thread size, these may need to be cleaned out with a tap/die or cut entirely.

d) Using wire erosion to separate the part(s) from the platen gives a high quality planar surface, utilise this in the part design if possible.

e) General finish will not be as good as a machined surface, but is this really necessary?

f) The more machining that is done post build, the greater the prospect that machining from solid will give a competitive solution. (Geometry permitting)

g) If the requirement is for an as machined finish then query the specification.

h) Don't get drawn into AM for the sake of it, but use it carefully. It is a powerful tool when used correctly.

i) Wrongly specified DMLS parts can cost a lot more than the alternatives out there.

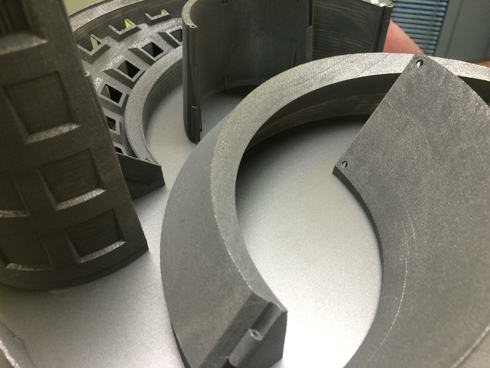

Finishing is labour is cost. Below we have compiled some examples of metallic parts produced using DMLS and that have had different finished applied, compared with CNC machined part that has had no post-processing.

Shot Peened Parts

Shot peening is a finishing process that employs the use of media to impact a surface with sufficient force to create plastic deformation. This process is similar to blasting except it operates on the mechanism of plasticity rather than abrasion. Shot peening is used primarily for deburring or descaling surfaces in preparation for additional post-processing (as per image above).

DMLS parts with CNC finish

Highly Polished DMLS parts

Highly Polished DMLS parts

CNC finishing permits high quality contoured milling applications to achieve tight tolerances. Proper fixturing can yield tolerances as tight as 1 micron, should this process be required, pre-build planning is needed to add sufficient material to machined surfaces and features so as to allow tolerances to be met.

High quality polishing can be achieved by manual, mechanical, or electrochemical techniques depending on the complexity of the geometry (see image right).

CNC parts

The image below is of an as built  CNC machined part, this part has not received any post-processing surface treatment. This finish was achieved using a 6mm cutter.

CNC machined part, this part has not received any post-processing surface treatment. This finish was achieved using a 6mm cutter.

DMLS has it’s advantages in being able to build complex geometries that are simply impossible to achieve via CNC but there are limitations with achievable surface finishes.

Unsure if your part is suitable for DMLS or CNC? Please don’t hesitate to contact us today and we will gladly point you in the right direction.

(DMLS images courtesy of ZARE S.M.L)