Which Shore Hardness do I want for my flexible part?

The Shore Durometer Test is the one we use most commonly due to the ability to measure the hardness of polymeric materials.

Different Shore Hardness Scales

There are several different Shore Hardness scales for measuring the hardness of different types of materials:

The Shore A00 Scale measures rubbers and gels that are very soft.

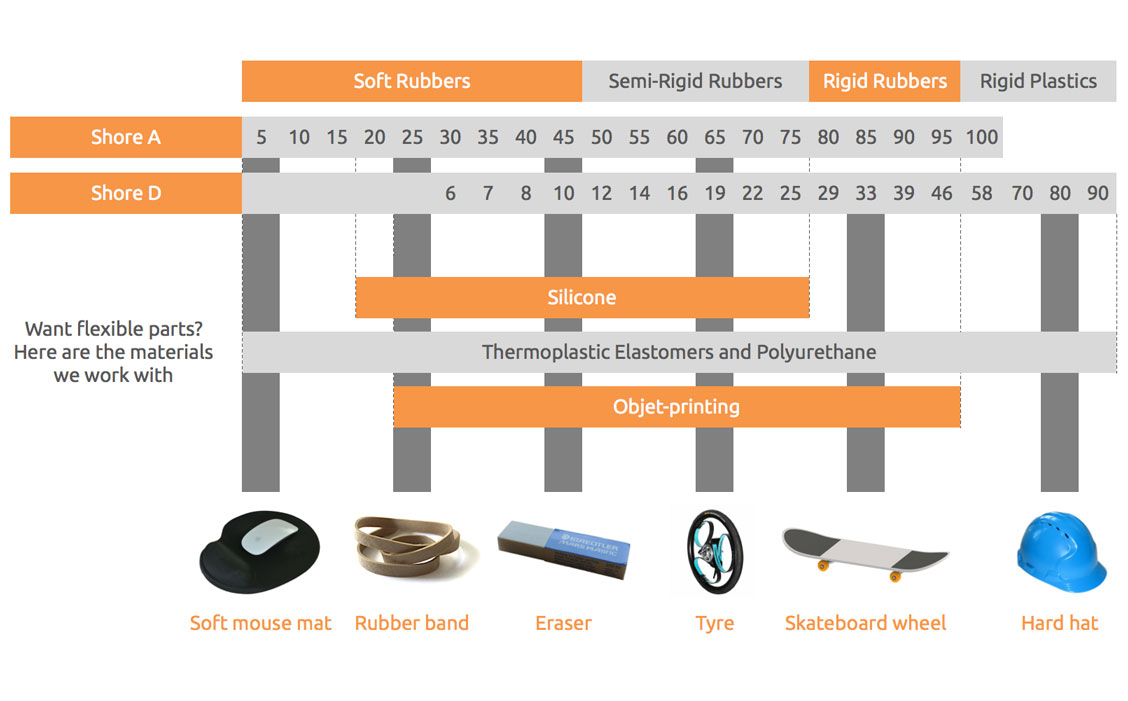

The Shore A Hardness Scale measures the hardness of flexible elastomerics that range in hardness from very soft and flexible, to hard with almost no flexibility at all. Semi-rigid plastics can also be measured on the high end of the Shore A Scale.

Shore D Hardness Scale measures the hardness of hard rubbers, semi-rigid plastics and hard plastics.

The differing scales measure the resistance of a material to indentation.

The differing scales measure the resistance of a material to indentation.

Shore Hardness Gauge

A ‘Shore Hardness' gauge (Durometer) has a needle on a spring protruding from one end. The needle is placed against the rubber or plastic and pressure is applied. Once the gauge is pressed firmly against the material and the needle has penetrated as far as it can go, the measurement needle will indicate the corresponding hardness measurement.

It is a relatively inexpensive, quick and easy method.

Because of the resilience of plastics, the indentation reading may change over time – so the indentation time is sometimes reported along with the hardness number. It is important to remember however, the Shore Durometer hardness test does not predict other properties well, such as strength or resistance to scratches, abrasion, or wear, and should not be used alone for product design specifications.

Scale overlap

There is overlap on these different scales. For example a material with a Shore hardness of 95A equates to Shore 45D as seen in the table below:

Hardness Swatch

Hardness Swatch

If you don't have a Durometer, we have developed a 'Hardness Swatch' – with swatches of Shore hardnesses ranging from 20 – 80 and with different thicknesses for touch and feel comparisons, this is the perfect way to help you decide, and describe, how flexible you want your part to be. These are available through us.

Ultimately, in order to select the right hardness, there are only two real ways forward. Option one is to use a Durometer on another product that feels right and the second is to prototype – something we would always recommend!

If you require a flexible part but are unsure how to measure it's hardness give us a call, we have years of experience and are able to help.