What are my options for clear prototypes?

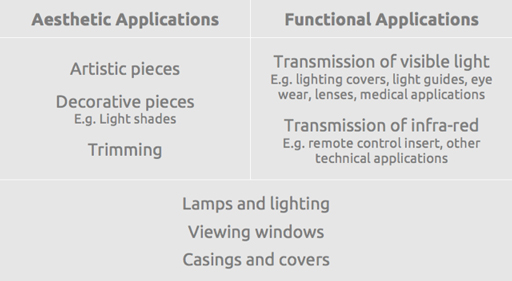

There are many applications where clear parts are required. This may be to improve aesthetics or there may be a functional requirement for a clear component, or it may be both of these.

Manufacturing clear parts can be challenging, even more so for additive processes due to restrictions on materials and evidence of layering inherent with additive processes.

Manufacturing clear parts can be challenging, even more so for additive processes due to restrictions on materials and evidence of layering inherent with additive processes.

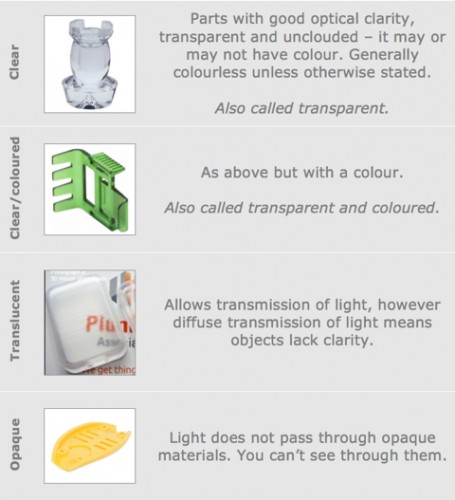

Defining requirements for clear parts can also represent a challenge due to different terminology. We’ve put together some definitions in the table below, which may help…

There are four main manufacturing process options.

CNC Machining

If the geometry and quantities are suitable then hand polished CNC machining would be our preferred manufacturing method using materials such as Acrylic (PMMA) or Polycarbonate (PC).

PC is preferred for applications where tougher material is required e.g. for scratch resistance, whereas PMMA is easier to polish.

Large parts can be fabricated and joined, if required, using specialist clear adhesives.

It is worth noting, manufacturing and polishing processes can result in stresses appearing within the part over time so it is important to work with an experience supplier.

As quantities rise it may be more cost effective to avoid hand polishing and use other manufacturing methods such as low volume injection moulding.

Low volume Injection Moulding

When injection moulding, the main investment is always the up front tool cost. Once the tooling is in place it is easy to make 100 or 10,000 parts.

PC or PMMA are again the materials of choice due to high optical clarity. PMMA may have a slight advantage in quality of clarity, whilst PC has slightly higher impact resistance.

Other material options include polystyrene, Methyl Methacrylate/ABS (MABS) and TPU’s (Thermoplastic polyurethane) for flexible clear parts.

Vacuum Casting

Vacuum casting offers a large range of clear polyurethane’s (PU’s) materials.

The ability of the silicone used for the mould, to replicate the smallest detail, is staggering. Hence getting good clear parts is all about getting an impeccable surface finish on the master used to cast the tool. Given this, the resulting cast parts will be truely clear.

Additive Manufacturing

There are three additive options – 3D Printing (Polyjet), Stereolithography (SLA) and a specialist optical additive process (which is generally reserved for specialist applications).

Post processing in each of these methods can improve the level of clarity but will add cost so it is worth considering what degree of clarity is required for your prototype.

The level of clarity is not quite in the same league as some of the other processes, but AM is more suited to low quantity applications and high levels of complexity.

There are more material options available for SLA, whilst Polyjet is limited in material, there are more options incorporating clear features into full colour prototypes, which can mimic the final product as well as clear flexible parts.

The best advice is to contact Plunkett Associates with the following information, and we will identify suitable materials:

- areas requiring clarity (or whole part)

- any environmental requirements, especially temperature

- aesthetic requirements, tinting, printing

.jpg)