Form and Fit

The need to validate ‘form and fit’ has long been a primary driver for prototyping.

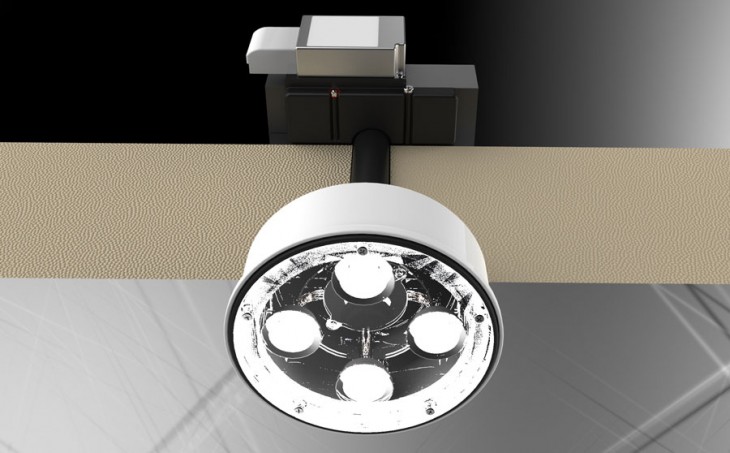

The advent of CAD (Computer Aided Design) allowed for the generation of shaded images that we now take for granted, and a huge step up in the ability to ‘see’ a design, especially for those not trained to read engineering drawings.

CAD images can aid design development

CAD has continued to develop and it is now possible to produce photo realistic images using the engineering data; an option we are more than happy to discuss with you. However, a physical prototype remains the first tactile example of an emerging design.

CAD has continued to develop and it is now possible to produce photo realistic images using the engineering data; an option we are more than happy to discuss with you. However, a physical prototype remains the first tactile example of an emerging design.

In the early conceptual stages of a design the primary issues are usually ‘form’ closely followed by ‘fit’, where we use fit to cover not just the component assembly but interfaces with electronics and associated componentry.

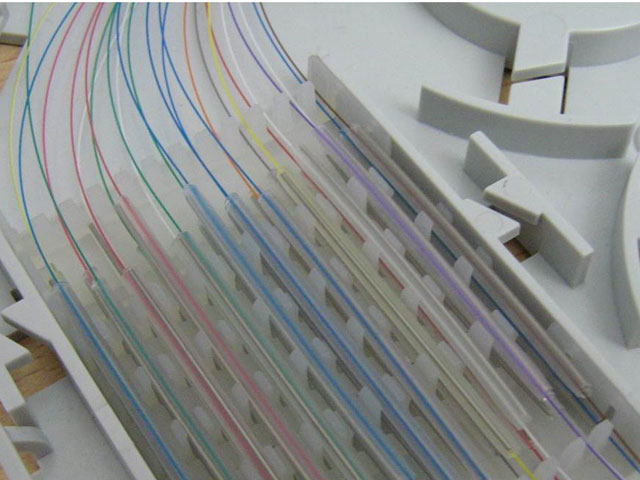

Physical prototypes remain the best way to test form and fit

Communicating ‘form’ can be very difficult and in ergonomic cases the derivation of the optimal design can be greatly enhanced through the use of physical prototypes and the feedback that they facilitate. Plunkett Associates have years of experience of developing and enhancing prototypes to get the best design for your part according to your needs.

Fit of part A to part B may be a simple issue, but upon installation, can features such as trims or adjusters be reached?

Fit of part A to part B may be a simple issue, but upon installation, can features such as trims or adjusters be reached?- In hydraulic situations, is there sufficient access to use standard tooling to make and tighten connections?

- More frequently planned or emergency maintenance has to be completed in a prescribed timescale, is this possible?

These are all questions that can be addressed.

Process selection is an important consideration for your prototype

So what is the impact of this on prototyping process selection? The most significant issue is one of materials selection. ‘Form and Fit’ places negligible requirements on the material used and a reasonable requirement on process accuracy.

So for example Stereolithography is a prime contender with its high process accuracy, but lower material toughness.

Another example would be compound curvature that can be produced both by layer based additive manufacturing and multi axis CNC machining.

Another example would be compound curvature that can be produced both by layer based additive manufacturing and multi axis CNC machining.

We know that to get a smooth surface the additive options will require a post manufacture dressing operation. In large parts this may not be an issue, however in smaller parts concern is frequently expressed over the manual nature of the dressing and the inherent lack of control. Opting for CNC Machining allows the production of a smooth surface directly from the CAD data.

CNC can be used as an option which allows for the manufacture of large parts (>500mm) with negligible loss of accuracy, and frequently very competitive costs when compared to additive options.

Plunkett Associates is here to ensure that you get the best from your prototyping experience. With no vested interest in any one process, we can offer truly impartial guidance on the options, and support you all the way from initial prototypes to subsequent tooling and production.

If this is what you are looking for, please give us a call or upload an enquiry here.