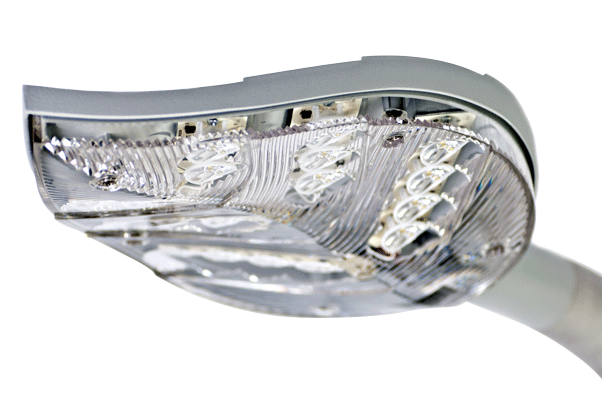

CNC polycarbonate provides high quality clear cover.

CNC machined aluminium give strength and aesthetics to high performance LED floodlight.

Requirements

Thorlux Lighting designs, manufactures and distributes a range of luminaires and other lighting products. Plunkett Associates has a long-standing relationship with the company and was asked to produce a fully functioning CNC machined prototype of a high performance LED floodlight – the Folio.

Plunkett Associates has a long-standing relationship with the company and was asked to produce a fully functioning CNC machined prototype of a high performance LED floodlight – the Folio.

Thorlux’s luminaires are subject to stringent quality control so the prototype had to be produced to a standard suitable for electrical, optical and environmental testing to ensure it complied with all relevant European standards.

Solution

The floodlight consists of a cast aluminium head unit with a polycarbonate cover. Plunkett Associates advised Thorlux’s design department on its options for producing a fully functioning, high quality prototype and sourced appropriate suppliers. CNC machining both parts from solid materials ensured a high level of optical clarity for the cover and a robust head unit that would withstand rigorous testing.

.png) Client

Client

“Producing CNC machined prototypes is an expensive process so we use Plunkett Associates because we want someone we can trust, that knows what they’re talking about, has all the contacts, will provide reliable advice and feedback and will get the right result for us.”

Jim Copestick, Design Office Manager

“We use Plunkett Associates because we want someone we can trust.”