Additive Manufacturing

Additive Manufacture has to be one of the most exciting possibilities to hit manufacturing for many years.

Offering a degree of design freedom that could never be envisaged with conventional manufacturing and a level of customisation that was previously impossible, its easy to get carried away!

Design rules must be adhered to

The media is full of how this new technology can make anything and how it will revolutionise manufacturing. What is seldom discussed is the associated cost and the design rules that must be applied if success is to be delivered.

Having been actively involved with what we now term 3D printing or additive manufacture (including DMLS or laser cusing) since the early 90’s and pioneered many of the applications that we now take for granted, we have the experience to guide you through the options without losing sight of the alternatives.

The starting point is as always the design, and the need to consider the manufacturing process in parallel with its formulation is something we are experts in and are well able to help you with.

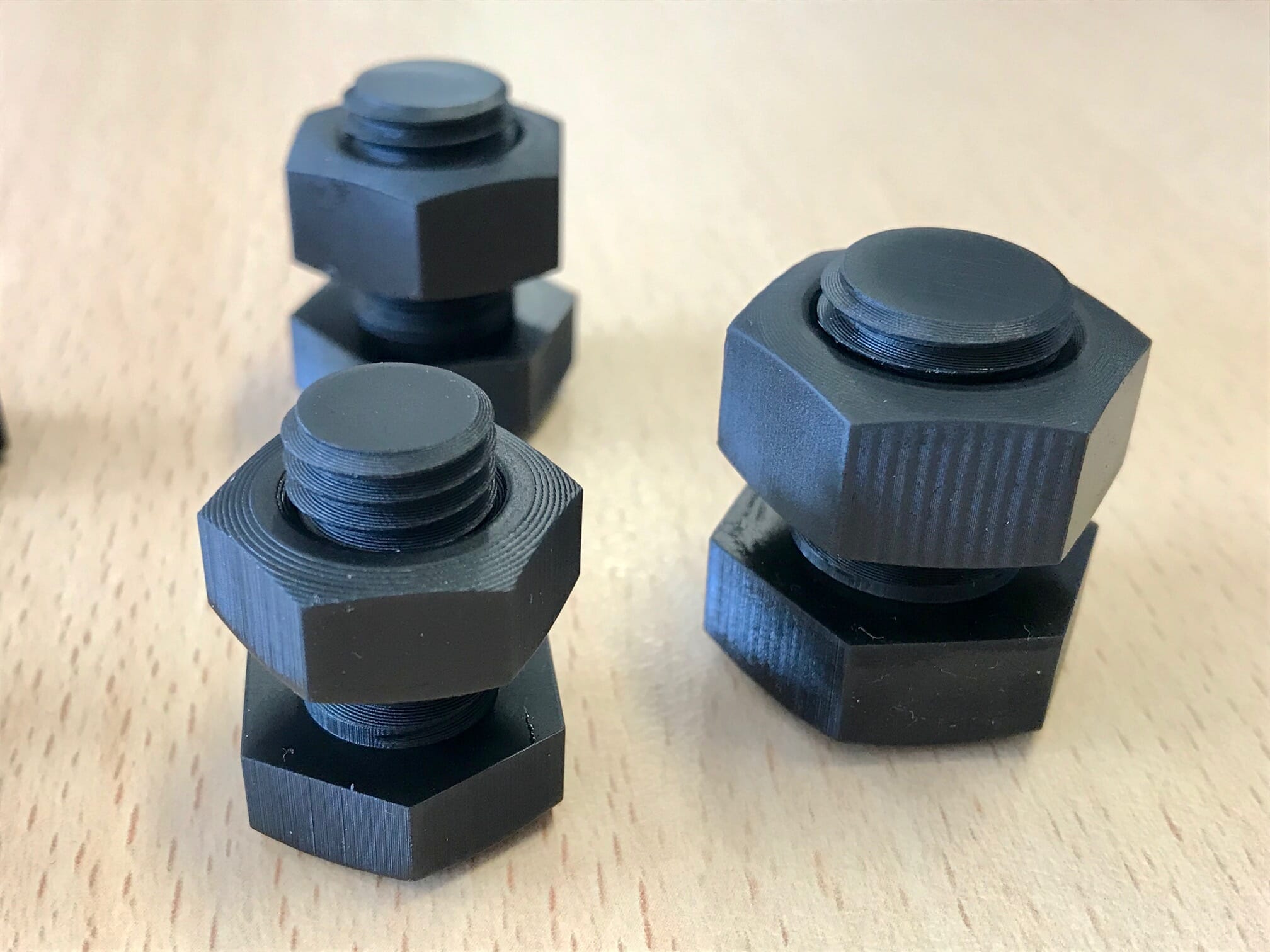

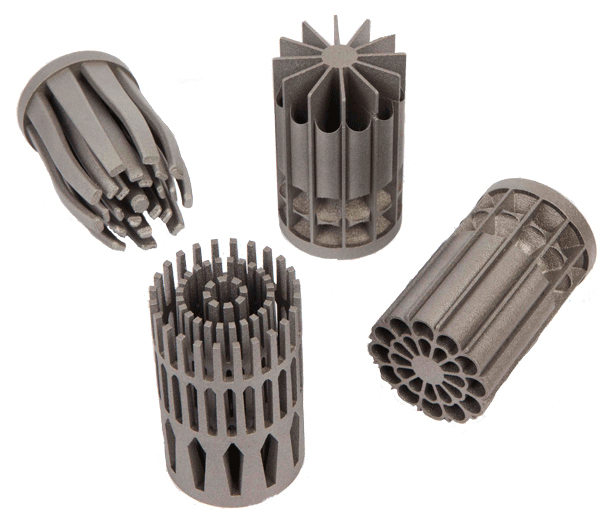

- We can build hollow structures.

- We can incorporate internal lattice structures.

- We can work with cobalt chrome, aluminium, steel titanium and polymers.

The art is to do this whilst delivering a competitive advantage be it cost, performance or function.

Parts must be designed for the process

To take a conventionally machined part and use additive manufacture to produce it, is most likely going to be a retrograde step. To take advantage of the potential, here at Plunkett Associates, we know the part must be designed for the process.

- We can incorporate the curved hole in lieu of multiple straight ones.

- We can combine components to do away with the fixings and assembly.

- We can optimise heat transfer and fluid flow paths in ways that were impossible before.

BUT only if we design for the process.

This does require a level of commitment. A design that uses additive manufacturing to its best advantage will not revert to conventional manufacturing strategy at a later date. It will be back to the ‘drawing board’ or more likely these days, the computer screen!

So whilst additive manufacturing as a technology is tremendously exciting and the possibilities are almost endless, there are rules to be followed to elicit success.

So whilst additive manufacturing as a technology is tremendously exciting and the possibilities are almost endless, there are rules to be followed to elicit success.

Design for manufacture is every bit as important as it always has been and we have the experience, interest and desire to help.

When you are ready, and it can seldom be too early, please give us a call or upload your enquiry here. We are ready, able and as excited as you to be part of taking your product to market!