Metal Parts

Metal Prototype and Production Parts. What are the options?

Metals offer a diverse range of properties and can be machined conventionally or additively (AM). When considering prototyping and production options it’s not just quantity, but size and geometry that will certainly influence the process choice.

Prototyping Metal Parts

Prototyping Metal Parts

Custom metal prototypes are generally manufactured by means of CNC machining or by additive manufacture.

CNC machining offers the greatest range of material options and the best potential accuracy, but is limited by cutter reach and geometry. However, more and more we are pushing CNC to its limits with incredible results – it may be a traditional process, but it’s certainly not antiquated!

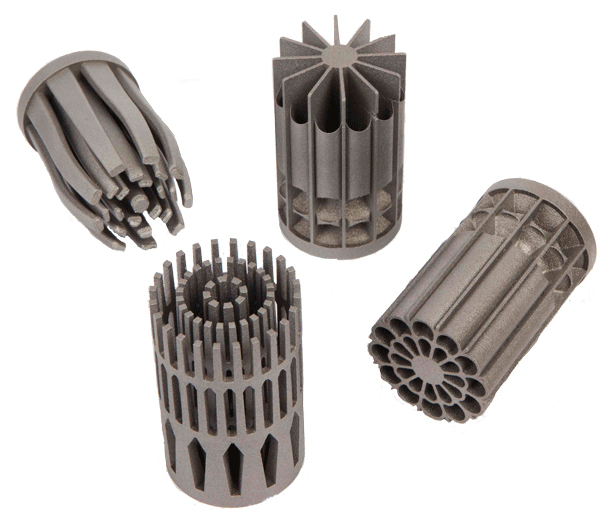

As rapid prototyping is becoming more popular, Direct Metal Laser Sintering (DMLS) is gaining ground as parts start to be designed exclusively for this process. DMLS is best suited to highly complex, small parts.

Before we go any further, be aware that in most instances metal prototyping is going to cost more than producing the equivalent part in plastic. So, the first question has to be, does it really have to be metal? Does the application warrant the additional cost?

Before we go any further, be aware that in most instances metal prototyping is going to cost more than producing the equivalent part in plastic. So, the first question has to be, does it really have to be metal? Does the application warrant the additional cost?

There are alternatives and it might be worth considering some of the interesting RP applications/materials out there, such as metal coated Stereolithography.

Material options

If metal is a definite, it is useful to determine whether a specific material is being sought, or whether a generic metal will do, as this again can have huge cost implications.

Most metal prototypes are in aluminium or stainless steel, however DMLS offers options such as Cobalt Chrome, Inconel and Titanium. Constraining the material to a particular grade or standard is likely to have a significant impact on the process options as flexibility is linked to the application.

Low volume Production

Low volume Production

It’s not just quantity, but size and geometry that will certainly influence the process choice. Complexity is “free” with additive techniques whereas CNC has to factor in the upfront programming time and fixturing required.

There are examples of high cosmetic CNC machined prototypes and DMLS parts on our gallery page or please contact us for further information or a quote.

As an ISO:9001:2015 Quality System certified supplier, we can supply the perfect solution for your metal part.