Pre-Production

There are times when the quantities of prototypes required rise well beyond the conventional 1 – 50 type range.

This may be due to the type of evaluation that is required, the number of people involved, or that they are really production items! Methods can vary but typically the greater the numbers, the closer the prototyping method gets to the production method.

Vacuum Casting

Vacuum casting whilst requiring tooling, has specific attributes that makes it attractive to producing quantities of large or complex parts. Vacuum casting can emulate colour and texture in a variety of grades of polyurethane (PU) resin, both hard and flexible.

Additive Manufacturing (DLP)

Additive manufacture processes such as Digital Light Printing (DLP) that provides a highly detailed finish, can be applied very effectively to parts that will be moulded or machined, and can be produced in a fraction of the time.

There can often be several weeks to wait whilst injection mould tooling is being manufactured and this additive process is often used to produce the first few batches and bridge the gap. Production quality parts can even be delivered the same day!

Additive materials have also come on enormously in recent years allowing us to get as close as possible to end use materials. With production grade materials readily available, working parts can be ready to use from Day 1 of design sign off. Polypropylene, ABS, rubber and even flame-retardant parts can be replicated with a range of high-performance resins to suit a vast range of applications.

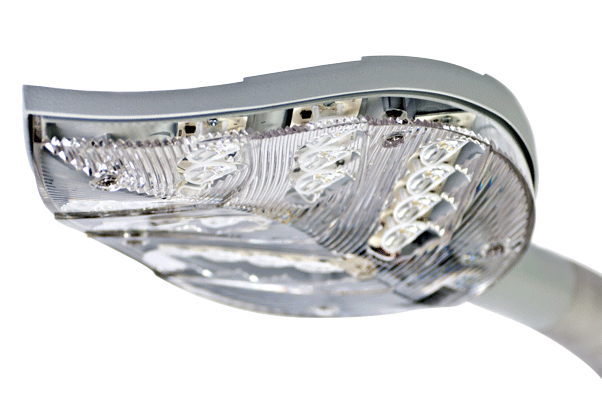

Injection Moulding in Low Volumes

For injection moulded plastic parts, we now offer a range of tooling options, several of which move this process firmly into the pre- production arena. Lead-times can be competitive with vacuum casting and depending on quantities, price can be competitive as well. All with the significant upside of having prototypes in production intent materials!

By leveraging the speed and high-specification materials through additive manufacture alongside our moulding capability we can help you move seamlessly from sample parts to production.

Plunkett Associates have the added advantage of having additive manufacture and tooling and moulding engineers all under the same roof, so communication between all parties is easy and instant. We can often compress development timescales by validating tool design changes with production quality samples the same day.

CNC Machining

CNC Machining

If the requirement is for metal components, these are frequently machined and post processed, as the production items would be, just in significantly shorter lead-times.

Under the pressure of time, CNC machining from solid will often offer advantages over casting and post machining, so long as the geometry permits.

Plunkett Associates provides a multitude of options to ensure you get the best possible from your pre production parts and can support you from initial prototypes through design approval/launch to subsequent tooling and production.

If you are in the early stages of your development project, please get in touch to find out how we can help you plan a smooth transition for your future production requirements.