2d-3d translation

Whilst the cost of 3D modeling software has fallen substantially over the years, not everyone has the skills, access or time to generate the 3D computer models necessary for manufacturing a new design.

If this is you then don’t worry! However your ideas exist, be it sketches, 2D data, concept drawings, artists impressions or even early handmade prototypes, we can help.

If you need a full design service, we can supply it. Alternatively we can work with the drawings you have to create the 3D information necessary to drive today's manufacturing methods.

Whatever the starting point for your idea, we can work with you to create the necessary data for prototypes or manufacturing.

With 3D data this will not happen, the full surface or solid is defined with no ambiguities.

3D data removes potential errors in translation during manufacture

When it comes to manufacturing, we always aim to use the 3D data to programme from, again removing possible sources of ‘translation’ error.

Thus if existing part definition is a 2D drawing (and assuming this has not been created from a 3D model as this would mean a 3D model was available!) our first step would be to create the associated 3D data, find any issues, and resolve them for you.

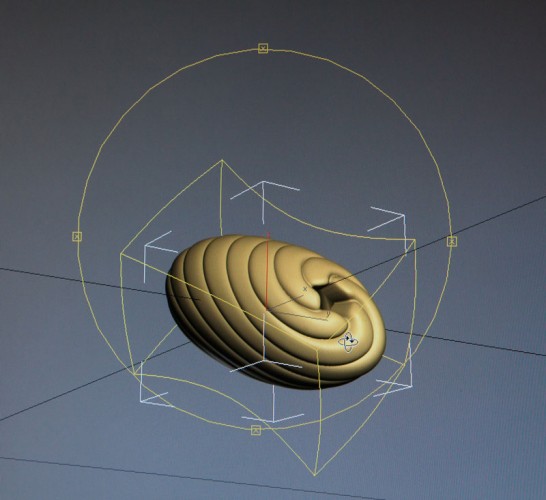

Generating this information facilitates not only manufacture but opens up other opportunities to use the data as can be seen here. At this point we can add features specific to the relevant manufacturing process for your component such as draft, fillets, a parting line, coring etc.

Control drawings are linked to the 3D model

Control drawings are linked to the 3D model

From the 3d data we can then generate new control drawings that are linked to the 3D model. These would typically contain information that is not held in the model itself, such as thread details, surface finish requirements, and tolerances. The only dimensional details would be critical features used for inspection, as these drawings are not designed as a stand alone component description, but are read in conjunction with the 3D model.

Even in the rare circumstances where a part is to be manufactured by cnc machining (conversational programming) on the shop floor we would still advocate the above process albeit with the production of a fully dimensioned drawing. Discovering an issue at this point in the process can result in significant delays in delivery, a consequence that is generally unpalatable!

.stp and .igs data required alongside .stl files

There are occasions when we are approached with .stl data files. These are only suitable for driving additive manufacturing or 3D printing systems. Thus if components are required to be injection moulded or cnc machined, the data will need remodelling to facilitate the creation of .igs or .stp file. This can be more drawn out than working from a drawing and is usually unfortunate as to get to the .stl file there was almost certainly a 3D model at some point in the past. (Hence it is always worth ensuring that you get native and .stp or .igs data from anyone undertaking CAD work on your behalf, not just an stl file!)

At Plunkett Associates, we run Solidworks, a comprehensive 3D design software which allows our experienced design engineers to add value to the development of your concept making it suitable for manufacture and beyond. For more information please give us a ring or contact us here.