Be the first to hear our latest news

What are my options for prototyping in glass reinforced nylon?

Jun 07, 2022

What are my options for prototyping in glass reinforced nylon?

There are a number of options when it comes to increasing the stiffness of polymer parts. The most common method is to use glass fillers.

These can come in the form of beads, fibres, or a combination of the two. Beads are more cost effective, not directionally dependent, and provide a better surface finish. However, they only provide an increase in stiffness, with little to no change to mechanical strength. Fibre fillers provide large increases in stiffness and strength, but mechanical properties are anisotropic, dependent on the fibre orientation.

There are a number of methods used to produce parts with glass filler.

Find out More –

- Injection moulding

- RRIM (Reinforced Reaction Injection Moulding)

- CNC

- 3D Printing (SLS)

- Pre-preg (carbon fibre lay-up)

The effects on mechanical properties, for the processes we use, due to fibre orientation are covered below:

Injection Moulding

When injection moulding a part, fibre orientation can be controlled, with the design of the tool, to ensure optimal fibre orientation within a part, and therefore access to the highest mechanical strengths given in datasheets.

CNC Machining

When CNC machining a part, it can be assumed that the block of glass filled nylon will contain fibres largely oriented in a single direction; the direction the block was extruded in. Without specialist equipment it is not possible to identify fibre orientation within the raw material when processing it. Therefore, any part that is machined will have fibres orientated in a single, unknown, direction. Thus, fibres contribute to stiffness, but in an uncontrolled manner.

SLS (Selective Laser Sintering)

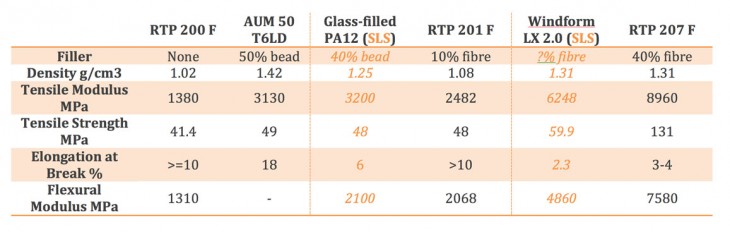

The preferred method to produce glass filled 3d printed parts is by SLS, utilising a glass bead filled nylon. In addition to the glass bead filled nylon, a company called CRP produce a glass fibre filled material: Windform LX 2.0. When compared with glass bead filled SLS, a large increase in stiffness and strength is observed, however this is directionally dependent, based on the process. Therefore any part produced will have fibres oriented in a single, known direction. Windform is of limited availability, however other fibre filled SLS materials are more readily available.

As can be seen in the table above, a part produced using glass bead filled PA12, via SLS, can be considered to have comparable properties to a part produced using 10% glass fibre PA12. This makes glass bead filled SLS a reasonable choice for producing functional prototypes. However, it must be noted that the surface finish is not as good as CNC or injection moulded parts.

Whatever your requirements, pick up the phone or send us an enquiry; we will be happy to discuss the options with you.