Be the first to hear our latest news

Moulding of PPE visors begins in just 4 days from design sign off!

Apr 23, 2020

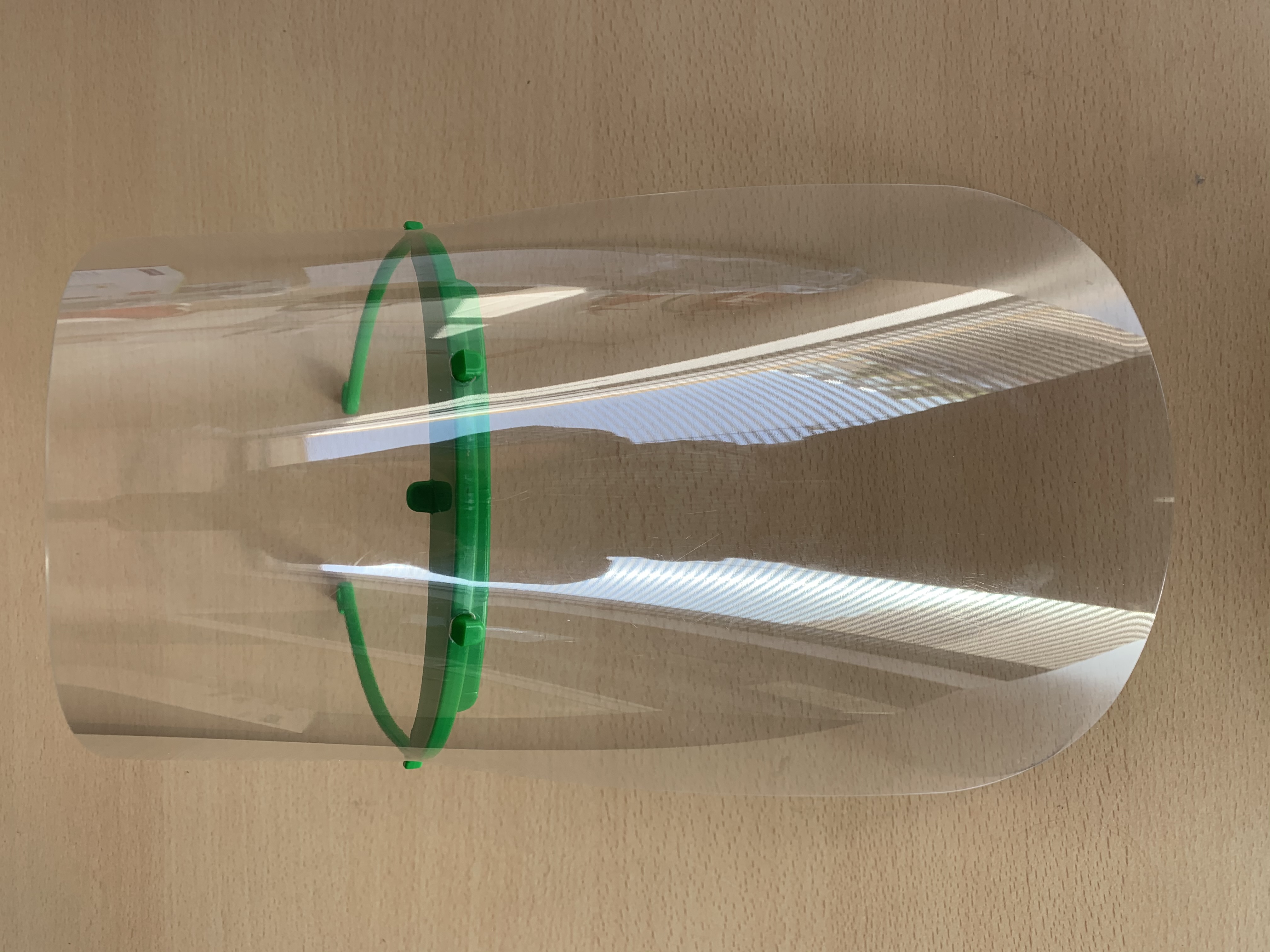

With the current urgent requirement for PPE by all healthcare sectors, we were approached by Resource 12 regarding the production of single use visors. They had a design that was currently being 3D printed however there was a need to scale up production.

Plunkett Associates was tasked with adapting the design to make it suitable for injection moulding with the aim going forwards to manufacture two aluminium single cavity tools and a full production twin cavity steel tool.

Prototypes were made to check form and fit, and a single cavity tool was trialled to test the material and mould.

4 days from design sign off and we are running at 3,000 parts a day with a view to producing over 70,000 parts a week once the subsequent tools are operational.

Parts are shipped to Resource R12 for assembly before being sent out to those most in need and the process of gaining CE accreditation to ensure the visors are of the best possible standard is also underway.

We are delighted to say the project is proving to be a huge success, with moulding well able to support the capacity for high volume production.

Our thanks to Resource 12 for their commitment and providing much needed support to our health professionals at this time.