Plastic Parts

With considerable choices for producing plastic parts, let's look at the options.

From 3D Printing to CNC Machining, Vacuum Casting to Injection Moulding, the process options for plastic parts are limitless.

Custom Prototyping

The decision making starts straightaway! With Stereolithography (SLA), Selective Laser Sintering (SLS), Multi jet Fusion (MJF) and Fused Deposition Modelling (FDM) there is considerable choice when prototyping custom plastic parts.

However, with all the hype around 3D Printing techniques it is easy to overlook the other more established options, such as CNC Machining, which remains a very cost effective solution, especially for larger parts and functional materials.

As quantities rise, tooling options are also most definitely worth considering even for surprisingly low numbers.

Transitioning from Prototyping to Production

Transitioning from Prototyping to Production

Transitioning from prototyping to production quantities can be a challenge, and rather than automatically jumping to additive manufacture for first prototypes, it may be worth considering the long term requirements (if you know them) first.

Design for manufacture is important, despite the hype that 3D Printing can do anything! The catch is that features get designed in that either prohibit conventional manufacture or make it unnecessarily expensive.

Let’s look at the options.

Rapid Prototyping (RP) is ideally suited to handling high component complexity. It provides a fast and economic means of validating such designs before tooling release.

Low Volume Production Plastic Parts

Low Volume Production Plastic Parts

Despite the growth of RP, CNC machining still plays a significant part in plastic custom prototyping and low volume production and should not be overlooked as a viable option.

Material choices are wider and when combined with our global sourcing, the results we can give you are often extremely economically attractive.

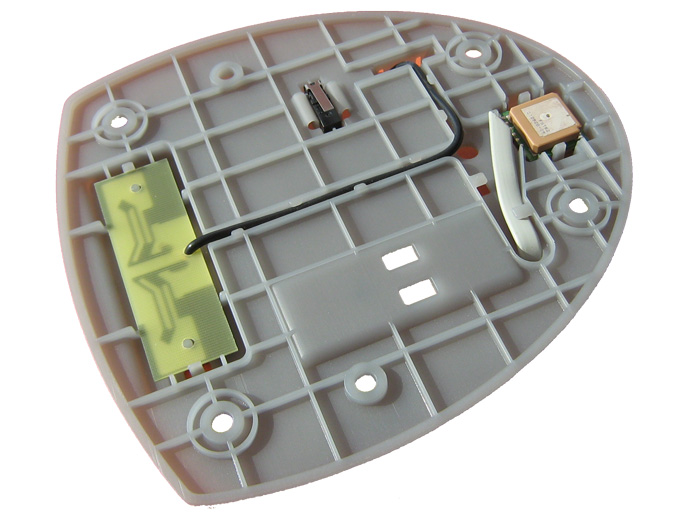

Vacuum casting is the first step into tooling; this process offers good part detail, which along with a range of polyurethane material options, provides an easy, cost effective transition into the production of plastic parts. Depending on the part geometry and material choice, tool life is typically 15 – 25 off.

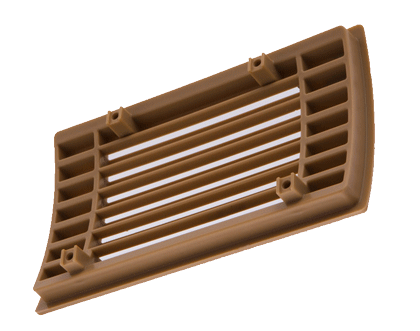

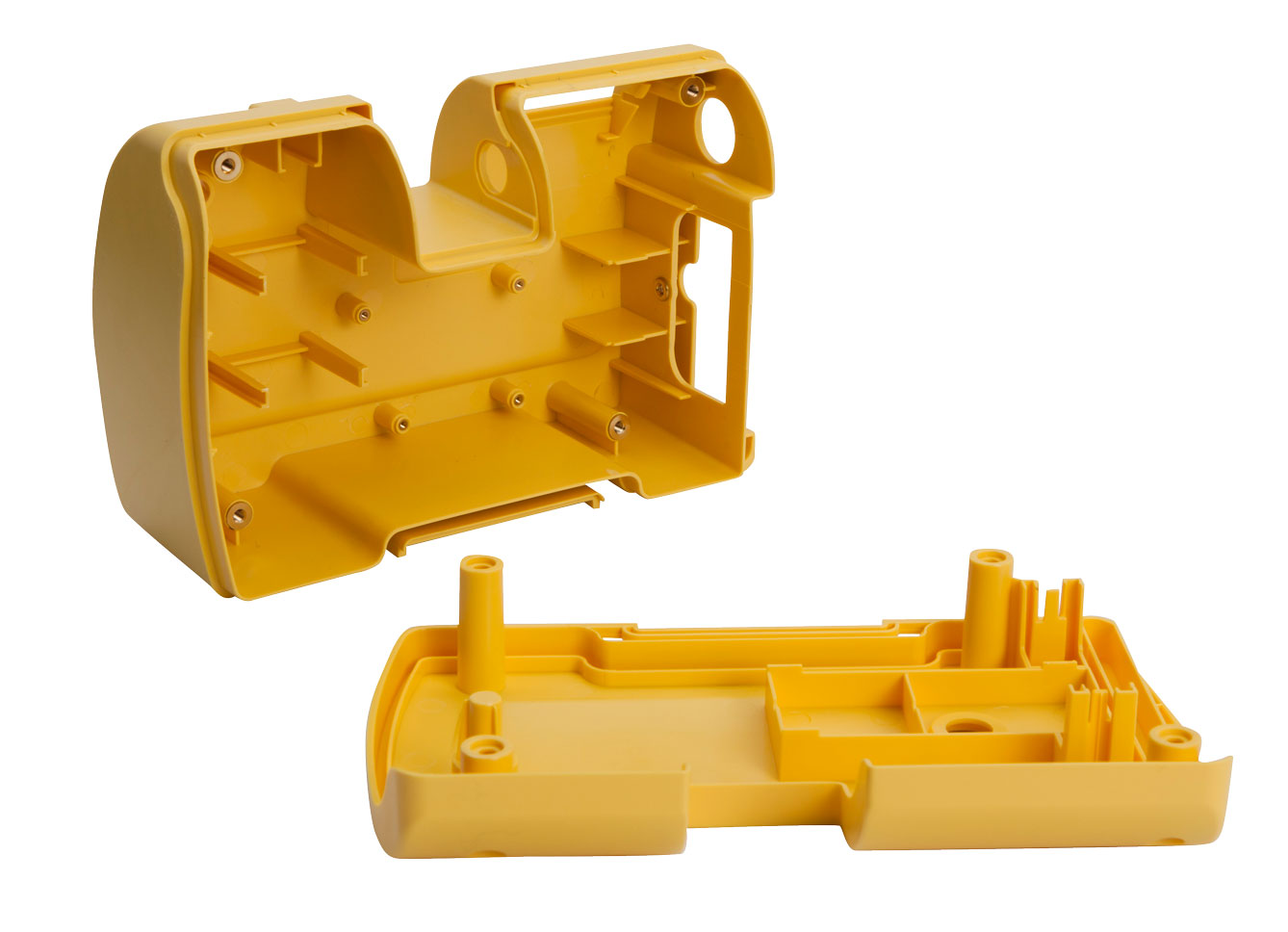

The flexibility of Injection Moulding – even for low volumes

Injection moulding still dominates the production of the majority of plastic parts, and whether combined with bridge tooling or full production tooling, offers a consistent high quality source of parts.

Usually considered to involve long lead times and high costs, this is not always the case and is really a case of matching the requirements to the type of tooling produced.

Moulding a handful of parts is very different from 100,000 parts but as specialists in low volume quantities, this is something we can help you with.

Why would you consider injection moulding to make just a handful of parts? There are several answers, but the ones we come across most frequently relate to materials. It delivers the production intent material and, once the tooling is in place, parts are available quickly and at low cost.

Visit our FAQ’s for more information on options for custom plastic parts. Or alternatively, give us a call. As an ISO:9001:2015 Quality System certified supplier, we can supply the perfect solution for your part.