Clear Parts

We have a range of solutions to meet all requirements for clear or translucent plastic parts.

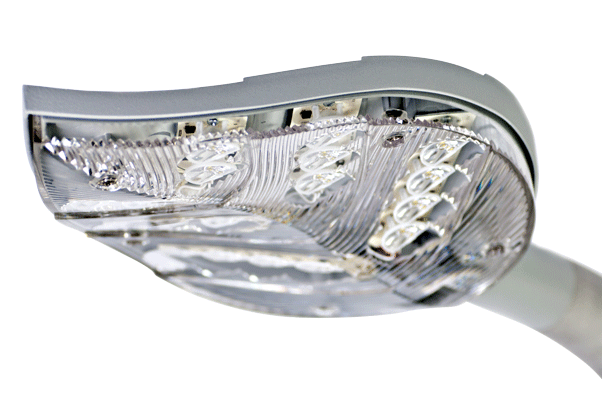

Many assemblies include clear component(s), the clarity required being dictated by the application. Whilst translucency may be sufficient to detect whether an LED is on or off, lenses, lightpipes and displays all require good optical characteristics.

Levels of clarity

First it is imperative to understand the level of clarity required, as this will have a direct bearing on the process options:

Optically Clear – Parts with good optical clarity, transparent and unclouded. (May or may not have colour.)

Clear – Clear at first glance, but not polished to the level of an optical finish.

Translucent – Allows transmission of light, however diffuse transmission of light means objects lack crispness.

Opaque – Light does not pass through opaque materials. You can’t see through them.

The usual options for optically clear through translucent parts are glass or plastic. Whilst glass becomes practically impossible as soon as you move away from fundamentally flat geometries, there are far more options for clear or translucent plastic parts.

We can produce custom clear parts from CNC machining, vacuum casting, injection moulding, or rapid prototyping techniques. The degree of clarity required, part complexity, quantities and timescales will all determine the appropriate process.

Prototyping clear parts

For low volume clear parts the ultimate solution, in terms of clarity, has to be to use CNC machining and hand polishing in materials such as Acrylic or Polycarbonate. PC is preferred for applications where tougher material is required e.g. for scratch resistance, whereas PMMA is easier to polish.

Obviously, the nearer the manufacturing process can get to a smooth finish, the less polishing is required. Less polishing means less labour and therefore less cost. From this perspective, CNC machining has an advantage over additive manufacturing techniques, where the layering will always need to be dressed.

There are three additive options – 3D Printing (Polyjet), Stereolithography (SLA) and a specialist optical additive process (which is generally reserved for lenses).

Post processing in each of these methods can improve the level of clarity but will add cost so it is worth considering what degree of clarity is really required for the prototype.

The additive options are ideal when complexity is high, but this can be deceptive. The optimal clarity requires dressing and this may not always be possible on complex parts. Lacquering is also frequently undertaken to improve clarity and can make a big difference, even with parts that have not been polished.

Low volume production

As quantities rise, we would then move away from hand polishing a part, to polishing a tool that can then impart the required surface finish to the part, through vacuum casting or injection moulding.

Vacuum casting offers a large range of clear polyurethane (PU) materials. The ability of the silicone used for the mould, to replicate the smallest detail, is staggering. Getting good clear parts is all about getting an impeccable surface finish on the master used to cast the tool, resulting in the cast parts being truly clear.

When injection moulding, the main investment is always the up front tool cost. Once the tooling is in place it is easy to make 100 or 10,000 parts.

PC or PMMA are again the materials of choice due to high optical clarity. PMMA may have a slight advantage in quality of clarity, whilst PC has slightly higher impact resistance.

As an ISO 9001:2015 Quality System certified supplier, we offer a range of solutions for custom clear parts to meet all requirements, including hand polished acrylic and polycarbonate to allow function testing.

If you would like to know more about process options for custom clear prototype and production parts please talk to us today. We will be happy to discuss your project with you.