Be the first to hear our latest news

Extending our services with new local supplier of high quality tooling, turning and milling!

Jan 12, 2017

It is imperative for us to ensure that client’s expectations are being exceeded wherever possible. One of the main ways that we endeavour to achieve this is through management of our supplier network.

We have recently brought on board a new local supplier who is able to provide us with high quality tooling, turning and milling services using state of the art modern CNC machinery. With their main business centring around utilising an array of lathes at their disposal, this supplier is able to produce components for a range of industries including Aerospace, Oil & Gas, and Medical in both low volume (up to 50) and high volume (100,000+) quantities, satisfying both prototype and production needs.

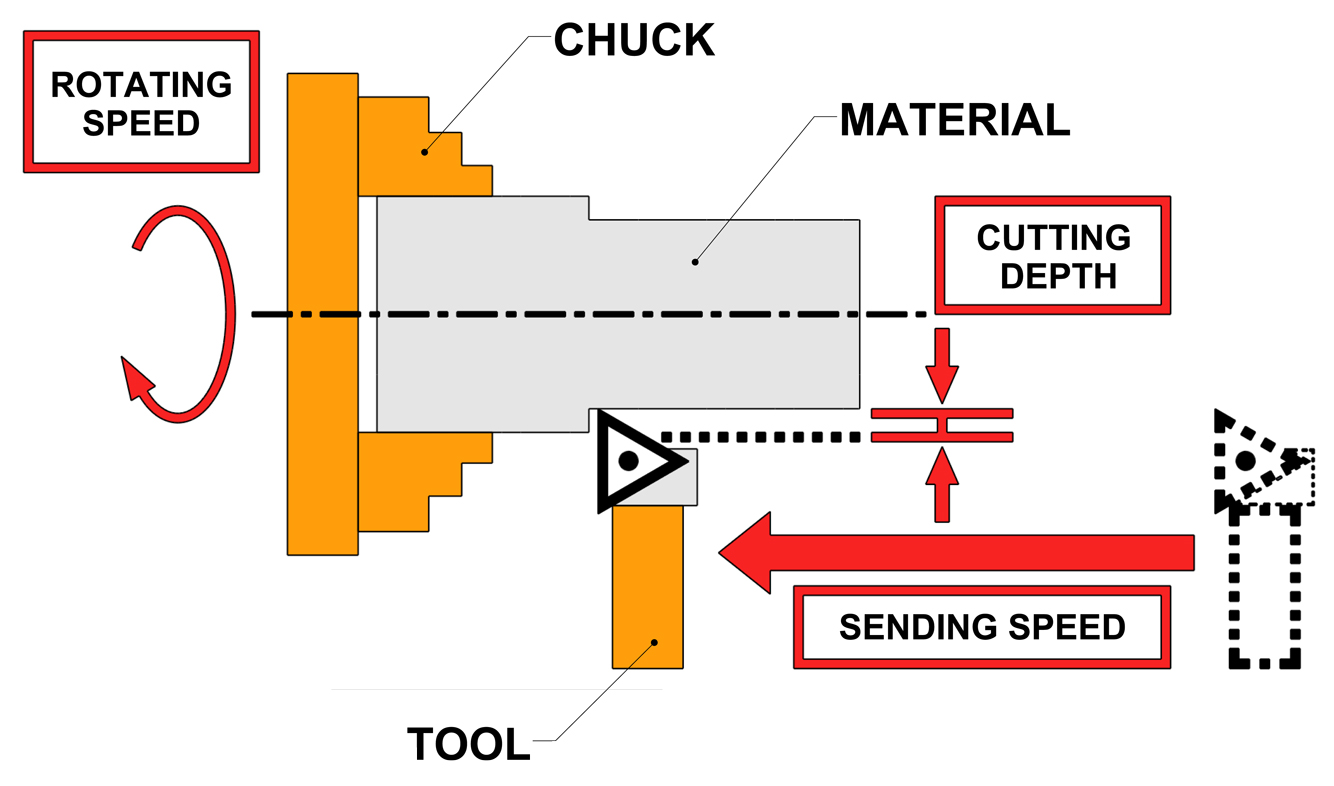

Basic Lathe Operation

Simply put, a lathe is a machine tool which spins or `turns’ a cylindrical workpiece and removes material by touching a cutting tool to it like that shown below.

Modern Lathe Operations

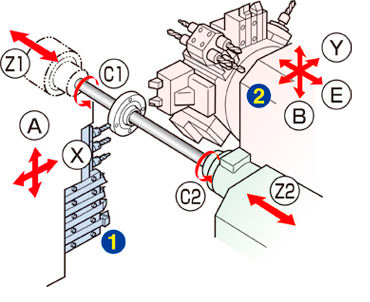

It is not uncommon nowadays to see 7-Axis lathes in operation, their functionality allows for increased part manipulation to produce the level of design previously unachievable. The diagram below gives an indication of that level of manoeuvrability.

3 axis for the tool up/down and tool bed right/left and to/fro

1 axis to spin the tool

1 axis to spin the workpiece

1 axis to rotate the tool head

1 axis to work the back of the piece

Specialising in precision engineering, this supplier is experienced in producing high quality components using a range of materials including steels, alloys, and plastics to within 0.01mm tolerances. Their high-volume machines are capable of producing components from 0.22mm to 20mm diameter bar feed in autonomous, 24/7 operations such as those shown here.

Their low volume machines can accommodate a bar stock of 80mm and a chuck part of up to 358mm diameter to produce components such as those shown in the two examples below.

Their low volume machines can accommodate a bar stock of 80mm and a chuck part of up to 358mm diameter to produce components such as those shown in the two examples below.

Turning can produce parts that are highly detailed and the process itself holds advantages over other methods such as Metal Injection Moulding (MIM) in that there is no need for tooling, the final component has a high-quality surface finish which reduces lead time, cost and the need for post processing.

This supplier also has the capability of producing parts via 2, 3, & 4-axis milling machines on site, which serve to compliment turned parts.

Don’t hesitate to contact us today if you think your project is suited to the above manufacturing method.