Be the first to hear our latest news

The Adept Mouldshop - what are we injection moulding now?!

Apr 21, 2019

My immediate reaction to the last year is that surely there isn’t that much to say! It’s been a bit of a blur to be honest and I’m not sure our feet have actually touched the ground!

My immediate reaction to the last year is that surely there isn’t that much to say! It’s been a bit of a blur to be honest and I’m not sure our feet have actually touched the ground!

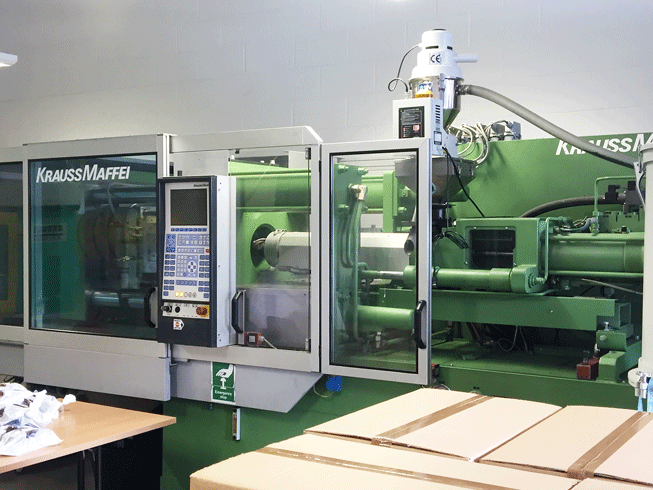

However when I look back over the last couple of years, I can see how far we have progressed in a very short space of time. It became very apparent pretty early on that our two injection moulding machines (80 and 120 tonne) were not going to be enough and with the opportunity of further premises, two more injection moulding machines arrived, this time 40 and 100 tonne, to help with existing clients rising requirements. We were off and moulding!

Our focus has always been to provide a fast, bespoke low volume injection moulding service and this remains our priority. Support and flexibility to the client and to their requirements, requires us to adapt and change as and when necessary. As such, discussions over alternative options or ways to push the boundaries further are always at the forefront of planning meetings.

Part of the reason for setting up Adept was the uncertainty of the political climate 2 years ago. One of the resulting services we have offered since was to provide the opportunity for clients to reshore their tools from the Far East back into the UK.

Our experienced moulder has successfully taken on several of these in the last year, not something every moulder is happy to do. This gives clients much needed security of knowing their tools are safely stored with the added bonus of parts now being UK manufactured and avoiding overseas shipping costs and import duties.

Batch sizes have grown and we now regularly mould 10 to 100,000 parts. With leadtimes always an issue, the need to run “lights out” has grown and we are currently looking into automation! We have already invested in a bagging machine that will print and seal bags – this makes packaging a much faster process and gives a very smart finish to the part. Our very first robot is on its way… and there are others in the pipeline, so watch this space!

Those of you that know us, know we don’t do anything by halves, so in the midst of everything else Adept Precision are in the process of going for ISO 9001:2015 Quality Management accreditation to give our clients peace of mind regarding our work system processes. Plunkett Associates, as the management company has been ISO 9001:2015 accredited for a number of years now, but Adept Precision has grown so much we thought it only fair to get this accreditation in our own right.

But this week, it was all about a brand new moulding machine! Up until now we have had the more traditional brands such as Kraus Maffei, Engel, Arburg and Boy but we’ve now decided to purchase a Yizumi – we’ll let you know how we get on with it…

(Whilst we’re talking machines: note to self – next on the list of things to do…find more space!)